Turbine Blade Inspection Using Vibro-Thermography

This article explores the application of vibro-thermography as an effective non-destructive testing (NDT) technique for detecting both surface and subsurface cracks in turbine blades.

NREL Invites Robots To Help Make Wind Turbine Blades

Although robots have been used by the wind energy industry to paint and polish blades, automation has not been widely adopted. Research at the laboratory demonstrates the ability of a robot to trim, grind, and sand blades.

Winds Of Change For Vestas: 3D Printed Tooling Transforms Wind Turbines

There aren't a lot of technologies that can propel towering wind turbines to new heights of time and cost efficiencies, but large-format additive manufacturing rose to the challenge and delivered with its eclectic range of applications.

3D Printing Powers Wind Turbine Research At TU Berlin

On average, wind turbine blades are a massive 80 meters long. When it comes to reengineering these towering blades, no other technology offers the freedom, precision, and adaptability to scale parts quite like 3D printing.

What Role Does Polymeric Technology Play in Burgeoning Wind Industry?

Designed to safeguard the integrity of wind turbine blade leading edges for the long term, polymeric repair and protection technology plays a critical role in supporting this burgeoning industry.

China Plans to Build a New Wind Farm and Develops Progressively Larger Turbines

A recently released report from World Forum Offshore Wind clarified that China is quickly becoming a major player in the offshore wind power market. The data indicated more than 70% of new global offshore wind power came from China in 2022.

EtherCAT measurement terminals in wind farm monitoring

By continuously monitoring the turbine, blades, and foundation performance, you can support decision making on planned maintenance and design validations, which in turn can help to avoid unplanned shut down periods or making costly repairs in the event of failure.

Monitoring the Condition of Your Plants With Vibration Sensors

To enable long-term monitoring of vibrations, Pepperl+Fuchs recently launched a new portfolio of vibration sensors. You can find out what distinguishes these products in the following blog article.

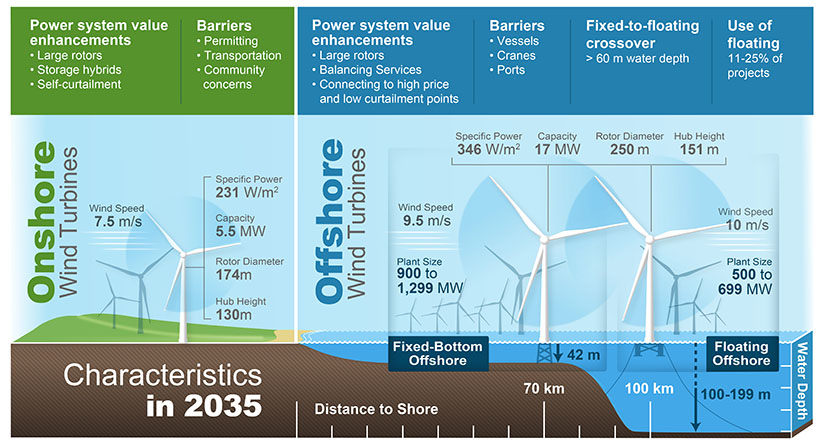

Experts Forecast the Wind Plant of the Future To Be Taller and More Economical

In the most-likely scenario, the experts predicted that hub height for newly installed onshore wind turbines will reach 130 meters in 2035, rather than the 115-meter forecast offered in a 2015 survey.

Why Are Wind Turbines Getting Larger?

Larger devices produce more emission-free electricity than smaller variants. Sustainability policies and regulations, like the United Nations (UN) Paris Agreement, may influence wind power's continuous expansion.

NREL Explores Innovative Manufacturing Approach for Next-Generation Wind Turbine Blades

Led by NREL senior wind technology engineer Derek Berry, the team's novel techniques could revolutionize how wind turbine blades are manufactured.

Records 1 to 11 of 11

Featured Product

Terrasmart - Reduce Risk and Accelerate Solar Installations

We push the limits in renewable energy, focusing on innovation to drive progress. Pioneering new solutions and ground-breaking technology, and smarter ways of working to make progress for our clients and the industry.

).JPG)

.jpg)