Due to the ranch’s remote location, the owner wished to build an off-the-grid building featuring a 3.84kW rooftop solar array together with a battery storage system to power the building. The rooftop solar modules are secured in place using the ProteaBracketTM by S-5!

Demolition Ranch HQ, Boerne, Texas―Case Study

Demolition Ranch HQ, Boerne, Texas―Case Study

Case Study from | S-5!

The Project

Demolition Ranch is the largest firearms channel on YouTube, receiving around a million views every day, and since its inception in 2011, it has amassed more than 11.5 million subscribers.

On location at the show’s gun range just north of San Antonio, is a newly constructed metal building housing supplies such as paint and ammo for making YouTube videos, in addition to a lounge area for taking breaks while filming.

Due to the ranch’s remote location, the owner wished to build an off-the-grid building featuring a 3.84kW rooftop solar array together with a battery storage system to power the building. The rooftop solar modules are secured in place using the ProteaBracketTM by S-5!

The Challenge

There is no electricity on the property. Installing electrical service was not a viable option, so the owner set out to build an off-the-grid facility. His total power needs included LED lighting, power tools, a mini-split air conditioning system, a small refrigerator and a small water pump (he also installed a rainwater catchment system for harvesting water for later use).

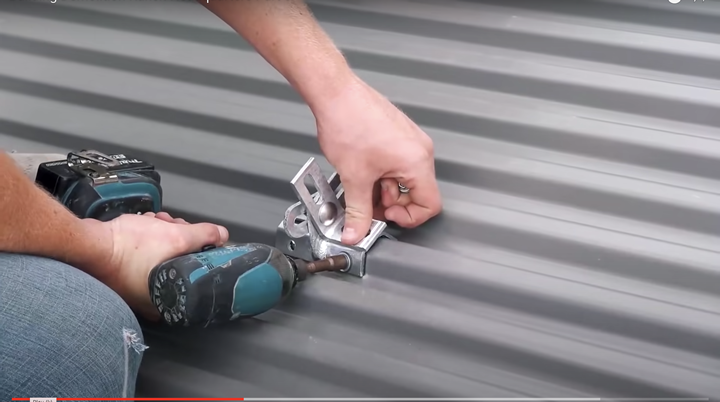

The challenge was to find a corrosion-resistant solar mounting solution for the building’s exposed-fastened metal roof profile that would withstand the area’s heavy rain and winds. Additionally, since the facility is located in the countryside, requiring contractors to traverse hilly dirt roads to the jobsite, transporting tools and materials presented logistical challenges.

The installer needed a solar mounting solution that was lightweight and compact to transport yet would provide a weathertight, secure dependable attachment to endure extreme weather conditions.

The Solution

Twelve solar panels were installed on the south-facing roof with room for additional panels on the remaining roof, should the owner choose to install additional solar at a later date.

A versatile bracket for mounting solar PV to trapezoidal metal roof profiles, the fully pre-assembled ProteaBracket fastens into the sheeting and features an adjustable attachment base to accommodate different roof profiles and module attachment options. Its pre-applied EPDM gasket with peel and stick adhesive makes installation a snap, ensuring accurate and secure placement and a weather-proof fit.

And since the ProteaBracket is light weight, it made transporting a cinch. Made of aluminum, the bracket enables a corrosion-free attachment.

The owner was able to achieve the quality look he wanted with a rootop solar system that would power his off-the-grid building for the headquarters of his YouTube channel.

Project Team

● General Contractor: Texas Barndominium

● Solar Contractor: Earth Smart Solar

● Solar Installer: Alamo City Solar

● Module Manufacturer: Mission Solar Energy

● Inverter Manufacturer: Sol-Ark 12K Inverter

● Battery Storage Manufacturer: Sol-Ark

● Solar Attachments: S-5!

Project Stats

● Roof Pitch: 3:12

● Roof Profile: 26-gauge WD Metal Roof D-Panels

● Solar Project Size: 3.84kW

● Solar Modules: 12 panels (320 watts each)

● Battery System: Sol-Ark (4 battery packs)

● Metal Building: WD Metal Buildings PBR Panels

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product