Harnessing hydrogen to power HGVs - Is hydrogen the solution to HGVs’ emission problem?

Heavy goods vehicles (HGVs) make up just 1.5 per cent of all transport, but produce 20 per cent of emissions. While decarbonising HGVs poses challenges, it’s a step that automakers must make to reduce emissions and meet global sustainability targets. Here, Simone Bruckner, managing director of automotive resistor manufacturer Cressall, puts forwards a case for hydrogen HGVs, and explains the role of resistors in making this shift.

HGVs keep the country running, with around 95 per cent of UK goods being transported by road freight during their life cycle. This figure continues to grow, with HGVs now carrying relatively more goods when compared to canals and railways than in 2000.

However, one of the UK’s most important industries is one of its least sustainable, as HGVs are the transport sector’s worst polluter. The UK government promises to have a zero-emission HGV fleet by 2040, although the recently announced delay on the ban of fossil fuel car sales shows this could still change. Nevertheless, even a delayed HGV deadline could still prove difficult to meet, as around 96 per cent of new trucks are diesel powered. So why are HGVs so difficult to decarbonise?

A key challenge is that, as the name suggests, HGVs are heavier than cars, and therefore require more power to carry loads. Additionally, HGV journeys are typically longer than those of other vehicles — with an average length of 66 miles compared with eight miles for cars.

Standard electric vehicle (EV) battery capacity may be insufficient for HGV requirements, making regular charging crucial. At the same time, limited charging infrastructure further reduces the feasibility of battery-powered HGVs.

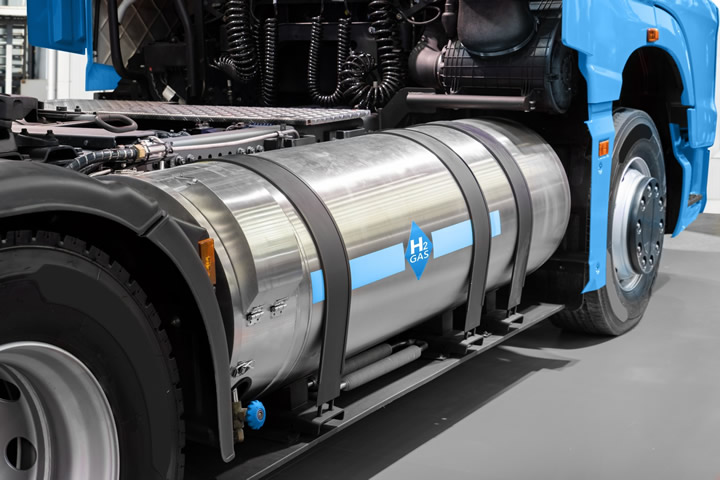

Hydrogen-powered HGVs

An increasingly popular alternative is hydrogen-powered fuel cell electric vehicles (FCEVs). Much like battery electric vehicles (BEVs), FCEVs provide a cleaner alternative to diesel HGV engines.

However, rather than being equipped with rechargeable batteries, FCEVs generate power using proton exchange membrane fuel cells. As hydrogen and oxygen react to produce an electrical current, the only by-products of the process are heat and water, meaning FCEVs do not emit greenhouse gases.

The absence of a rechargeable battery solves the issue of limited charging infrastructure, as FCEVs are refuelled by filling the vehicle’s tank with hydrogen. This means that hydrogen fuel pumps can be added to pre-existing filling stations on common HGV routes, as is being rolled out across Germany.

Convenient refuelling that enables HGVs to undertake long journeys could make FCEVs a viable alternative to diesel engines.

Energy efficient FCEVs

As hydrogen fuel cells become more common, we must look to increase their operating efficiency.

Fuel cell studies demonstrate that power output becomes unstable if FCEVs accelerate for prolonged amounts of time, as they cannot work under heavy loads for extended periods. Given the weight of HGVs, this fluctuation could reduce engine reliability.

Fortunately, automakers can combat instability by fitting cells with higher capacity than the vehicle requires. This means if power output decreases, HGVs still have the required amount of power available.

However, when excess energy is created, it is important to dissipate this energy safely to improve the HGV’s lifespan. This can be done by fitting fuel cells with a dynamic braking resistor (DBR), which disperses the surplus as heat.

Cressall’s EV2 DBR is particularly suited to fuel cell HGV applications. The resistor is water cooled — meaning it does not rely on heavy fans as is the case with air-cooled DBRs — and therefore is only 15 per cent of the standard DBR weight. Consequently, EV2 units are light enough that five can be combined at once, allowing them to handle power of up to 125 kilowatts. This makes them a useful solution for HGVs’ high continuous power requirements.

Although the diesel HGV ban does not take effect until 2040, it is never too early to consider hydrogen-powered engines. The DBR-enabled use of hydrogen cells could safely and effectively fuel the UK’s net zero transition.

Cressall has extensive experience supplying resistors to automotive projects. For more information on available products or to discuss your next project, get in touch with the team on +44 (0) 116 273 3633.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product