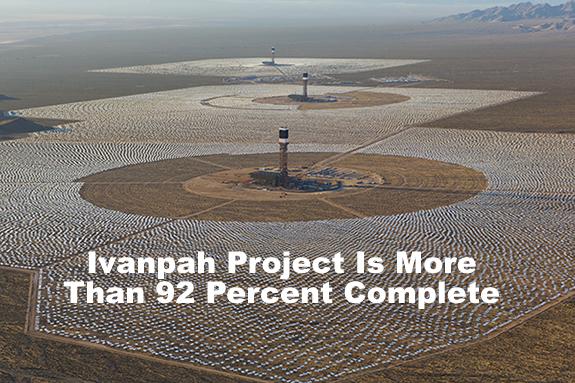

To date, more than 153,990 of the project's total 173,500 heliostats have been installed. Several stunning photos below show recent progress at the site.

Contributed by | BrightSource Energy

As the Ivanpah project nears completion, the team continues to move full steam ahead. During the months of February, March and April, more than 1,250 construction workers advanced the project to more than 92 percent complete! To date, more than 153,990 of the project’s total 173,500 heliostats have been installed. Several stunning photos below show recent progress at the site. For a slideshow of all the new photos, click here.

Photos by Gilles Mingasson/Getty Images for Bechtel.

Ivanpah Project Begins “Steam Blows”

In April, the Ivanpah team commenced “steam blows” at Unit 1. During steam blows, upwards of thousands of heliostats are focused on the solar boiler to achieve the desired temperatures, pressures and flow rates. The goal of the steam blows is to clear out any mill scale or debris inside the pipes so it does not damage the steam turbine and other balance of plant equipment once operational. A normal start-up process for any conventional power plant, steam blows are part of the “load ascension” program, which includes focusing an increasing number of heliostats onto the boiler and methodically raising the temperature and pressure of the steam produced. Learn more about steam blows here.

Construction Update

Common Area

In the Common Area, heliostat assembly continues at a brisk pace of 500 per day in the Heliostat Assembly Building and Pad Bonding Building. More than 34,500 assemblies were completed in February-April, bringing the total number of heliostat assemblies completed to date to more than 153,990 or 89 percent. The team also began to dismantle Common Area facilities that are no longer required.

Unit 1

Unit 1

Unit 1 is more than 95 percent complete. The team achieved an important milestone in the construction of the project on April 11, when the final heliostat was installed in the Unit 1 solar field, in the area nearest the tower. With all 53,527 heliostats now installed, it improves the team’s start-up capabilities. Atop the tower, the team continued the boiler’s load ascension program to support steam blows. Once the steam blows are complete, the team will remove the temporary steam blow piping and reconnect the piping to design conditions. The next step will be for the boiler to admit steam to the steam turbine. Once the steam turbine generator is synchronized to the grid, the plant will generate electricity to the grid. As more of the plant’s systems are turned over for startup, demobilization of construction facilities at the power block is underway.

Unit 2

Unit 2

On May 14, the Ivanpah team reached another major milestone in the start up of the plant when first flux was achieved at Unit 2. Solar flux is when a significant amount of sunlight is reflected off of the solar field mirrors and concentrated on a surface of the boiler. The flux slowly heated the water inside the boiler to just below the point of steam generation. Overall, Unit 2 is more than 92 percent complete. The team completed the chemical clean of the boiler’s evaporator section in March and began the restoration process in preparation for steam blows in the coming months. On the ground, the team has cleaned up the lay-down area and completed the berm. The installation of the Air Cooled Condenser (ACC) is complete, and the team successfully conducted an air test to confirm the integrity of piping and check for leaks. Insulation of the ACC’s piping and equipment, as well as electrical cable and terminations continues. In the solar field, more than 56,410 heliostats are installed. When complete, the Unit 2 solar field will feature 60,000 heliostats to produce 133 MW gross of clean electrical energy.

Unit 3

Unit 3 is more than 89 percent complete. In April, the team chemically cleaned the boiler in preparation for operation. In the power block, the team continues to commission various systems that support the boiler and is erecting the ACC wind protection walls. In the solar field, more than 47,700 heliostats of the unit’s 60,000 heliostats have been installed to date.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product