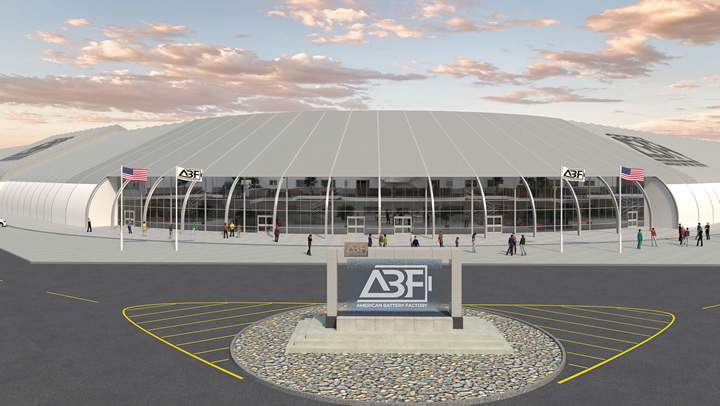

AMERICAN BATTERY FACTORY BREAKS GROUND ON LARGEST U.S. LITHIUM IRON PHOSPHATE BATTERY CELL GIGAFACTORY IN TUCSON, ARIZONA

American Battery Factory (ABF), an emerging battery manufacturer leading the development of the first network of lithium iron phosphate (LFP) battery cell gigafactories in the United States, today broke ground in Tucson, Arizona on a two million square foot gigafactory. The site will provide an estimated 1,000 jobs, $1.2 billion in capital investment and $3.1 billion in economic impact to Arizona while accelerating the growth of America's clean energy economy by utilizing the region's high-capacity border and transportation infrastructure to ship battery cells nationwide and globally.

The global market for lithium batteries is expected to reach $105 billion by 2025 with the demand set to increase 10 times over the next decade. ABF's battery cells are made with lithium iron phosphate chemistry, meaning the production of the safest, longest-lasting, most reliable and environmentally friendly batteries currently available. With these cells, ABF plans to transform today's single-source energy paradigm, opening the window for using software and technology to store an unlimited inventory of clean energy from sources such as solar and wind for use while also taking pressure off existing power grids.

"We are honored to implement our company's mission of global energy independence in Arizona, a premier destination for emerging technologies," said John Kem, president of American Battery Factory. "We are pleased to join this thriving region and look forward to enhancing Pima County's growing economy by fostering innovation while attracting and retaining residents to Tucson."

"Today's groundbreaking represents a significant milestone for Arizona's battery industry," said Arizona Gov. Katie Hobbs, who participated in the event. "With this transformational investment, American Battery Factory advances Arizona's clean energy industry and bolsters continued economic growth in Tucson and Pima County. I want to thank the entire team at American Battery Factory for their commitment to Arizona and all partners for their continued support to make this project possible."

Located on 267 acres in Pima County's Aerospace Research Campus – close to world-class companies such as Raytheon – ABF's gigafactory will be the home of energy storage innovation, with opportunities for new technology development. Utilizing rapid modular construction by Sprung Instant Structures, the company plans to have the headquarters, R&D center and initial factory module built by 2025. Using cutting-edge construction technology, the building will greatly limit waste at the site, be airtight and will ensure the protection of the battery cells during production.

The company has recently expanded its executive leadership team, adding former Major General John Kem as president and award-winning Dr. Jun Liu as chief scientist. The company has also secured strategic partnerships with companies like Celgard, Anovion and FNA Group as well as raised significant development capital to make its vision a reality.

ABOUT AMERICAN BATTERY FACTORY

American Battery Factory Inc., a Lithium Iron Phosphate (LFP) battery cell manufacturer, is developing the first-ever network of safe LFP cell giga-factories in the United States. The company is dedicated to making energy independence and clean energy a reality for the United States by creating a domestic battery supply chain. Along with creating domestic manufacturing jobs, ABF will play a crucial role in meeting federal and state government climate change initiatives and "Made-in-USA'' national security requirements. For more information, please visit americanbatteryfactory.com.

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product