As more industries turn to battery backups, the potential for dangerous thermal events like overheating or fires becomes a serious concern. Thermal cameras have emerged as a game-changing technology, transforming how fire prevention is handled in battery backup systems.

The Role of Thermal Cameras in Preventing Fires in Industrial Battery Backup Systems

Article from | MoviTHERM

In today’s tech-driven world, industrial battery backup systems are the backbone of uninterrupted business operations. These systems keep critical operations running smoothly during power outages, ensuring data centers, hospitals, manufacturing plants, and even telecom infrastructures can function without interruption. While their importance can’t be overstated, many overlook a looming challenge: the fire risk associated with these battery systems. As more industries turn to battery backups, the potential for dangerous thermal events like overheating or even fires becomes a serious concern.

Thermal cameras have emerged as a game-changing technology, transforming how fire prevention is handled in battery backup systems.

The Growing Fire Risk in Battery Backup Systems

Battery backup systems, especially those that use lithium-ion technology, are known to be at risk of overheating due to the high energy they store. Factors like overcharging, faulty wiring, or even small defects in the batteries themselves can result in a dangerous phenomenon known as thermal runaway. This chain reaction can lead to soaring temperatures, potentially igniting fires that are difficult to contain and devastating to any business operation.

Battery backup systems, especially those that use lithium-ion technology, are known to be at risk of overheating due to the high energy they store. Factors like overcharging, faulty wiring, or even small defects in the batteries themselves can result in a dangerous phenomenon known as thermal runaway. This chain reaction can lead to soaring temperatures, potentially igniting fires that are difficult to contain and devastating to any business operation.

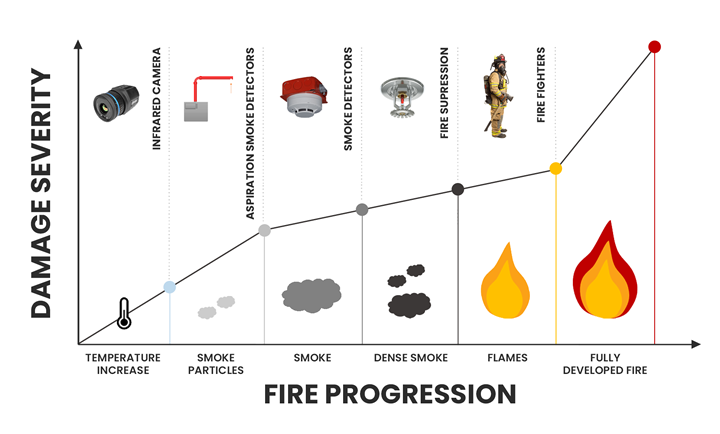

Traditional fire detection methods, such as smoke alarms or sprinklers, only react after a fire has started. Unfortunately, by that point, the damage to equipment, and the risk to people, can already be significant.

Thermal Cameras: A Game Changer for Fire Prevention

This is where thermal cameras come in. By continuously monitoring the temperature of battery systems, thermal cameras detect subtle changes in heat long before visible smoke or flames appear. These cameras provide real-time thermal imaging, which is critical in spotting overheating battery cells early on, allowing facilities to take preventive action before an actual fire erupts.

How Thermal Cameras Work

Thermal cameras use infrared technology to detect heat energy emitted from objects. When connected to monitoring systems, these cameras provide a live feed of temperature data, alerting facility operators if certain thresholds are exceeded. This early warning system can detect irregular temperature spikes that may signal malfunctioning batteries, faulty wiring, or general overheating.

The advantage? Industrial sites can now respond before an issue turns into a full-blown crisis. Facilities are given the power to shut down malfunctioning systems, address cooling issues, or conduct maintenance on problematic units — all before fire hazards manifest.

iTL System: Taking Thermal Monitoring to the Next Level

While thermal cameras are incredibly powerful, integrating them into a comprehensive fire prevention system is where the real magic happens. This is exactly what the iTL system provides.

The iTL system pairs thermal cameras with advanced cloud-based monitoring, offering 24/7 continuous surveillance of your battery backup systems. Not only does it monitor multiple thermal cameras in real time, but it also autonomously triggers alerts when high-risk temperature thresholds are reached. Whether you’re on-site or remote, the iTL system sends notifications via email, SMS, or even voice calls, ensuring you’re always one step ahead of a potential disaster.

Additionally, the iTL system offers valuable historical data, helping facility managers track temperature trends over time. This feature allows operators to identify patterns of gradual overheating, further enhancing proactive maintenance efforts. With its ability to integrate with both PTZ thermal cameras and fixed thermal cameras, the iTL system ensures comprehensive coverage, no matter the size or complexity of your facility.

Benefits of Using Thermal Cameras in Battery Backup Systems

Thermal cameras, combined with systems like iTL, offer a host of benefits for businesses utilizing battery backup systems, including:

- Early Detection: Identifying temperature abnormalities before they escalate into fires.

- Real-Time Alerts: Instant notifications that allow for immediate action to mitigate risks.

- Cost Savings: Preventing damage to valuable equipment reduces repair and replacement costs.

- Continuous Monitoring: Around-the-clock surveillance, even when staff is off-site.

- Improved Safety: Protecting both employees and facilities from the dangers of battery fires.

- Data-Driven Maintenance: Using historical data to identify long-term overheating trends, which can improve maintenance planning.

Why Fire Prevention is Critical in Battery Backup Systems

The failure of battery backup systems due to fire can have disastrous consequences, especially in industries that rely heavily on uninterrupted power. For example, data centers could face millions in losses from downtime, while hospitals risk life-threatening situations if critical medical equipment is interrupted.

By adopting thermal camera technology, businesses can significantly reduce the chances of fire incidents, ensuring their battery backup systems function safely and reliably. This not only protects the company’s bottom line but also reinforces safety standards for employees and customers alike.

Conclusion: Safeguarding the Future of Power with Thermal Technology

As industries increasingly rely on battery backups to power critical operations, the need for robust fire prevention strategies grows. Thermal cameras, paired with advanced systems like iTL, provide the ultimate solution — offering early detection, real-time alerts, and comprehensive monitoring to prevent fires before they happen.

When it comes to protecting your facility from battery-related fires, the smart move is clear: embrace thermal technology to ensure safety, continuity, and peace of mind.

Interested in learning more about how the iTL system can safeguard your battery backup systems? Contact MoviTHERM today for a demo!

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product