It’s a priority for many transportation and energy service providers to ensure the longevity and optimal performance of their batteries. By better understanding battery aging we can learn how to prolong the lifespan of batteries.

Ultimate Guide to Battery Aging - How to Prevent Aging in Battery Energy Storage Systems

Ultimate Guide to Battery Aging - How to Prevent Aging in Battery Energy Storage Systems

Article from | ACCURE Battery Intelligence

Key terms to know

This article will introduce many new terms around lithium-ion battery aging. Because not everyone is a battery expert, let me explain a few foundational terms to help us ease into the subject of battery aging:

|

Key term |

Definition |

|---|---|

| Capacity | Capacity refers to how much electric charge the battery can store, expressed in ampere hours (Ah). |

| Internal resistance | Internal resistance is a characteristic of each battery and can be considered a limiting factor to the power capability of a battery. It correlates to the internal losses generated when the battery is charged or discharged. |

| State of charge (SOC) | State of charge measures the remaining level of charge in relation to the maximum available capacity. |

| Depth of discharge (DOD) | Depth of discharge refers to the percentage of capacity that has been discharged from the battery relative to the total available capacity. |

How do lithium-ion batteries age?

Battery aging is very complex, non-linear and influenced by many parameters. It can be observed for example, that batteries age even if they are not used. But, in general, batteries age faster if they are used. To manage the complexity, it is common practice to split aging into three buckets: calendric, cyclic, and reversible aging:

- Calendric aging – The gradual degradation of batteries over time, even if they are not used. This is comparable to human aging – even if we do nothing all day, we still age.

- Cyclic aging – The “wear and tear” batteries sustain with each charge and discharge cycle. In other words, every time a battery is used, some degree of aging occurs. Coming back to the analogy to humans, some of us age faster under high workloads or stress.

- Reversible aging – While cyclic and calendric aging describe irreversible aging effects, reversible aging like the anode overhang effect describes aging mechanisms that can increase battery lifetime.

When batteries age, different aging mechanisms take place simultaneously. Each aging mechanism has an impact on the behavior of the battery. The impact can be broken down into two performance parameters: capacity and internal resistance.

Capacity degradation

Batteries lose capacity when they age. For an electric vehicle, losing capacity means the EV cannot drive as far as it used to without stopping for a recharge. And for stationary energy storage, it means the battery can store less energy and thus generate less revenue. How fast the capacity decreases depends on a number of factors including the type of battery, the charging and discharge rates, the temperatures it is exposed to, and the number of cycles it has undergone.

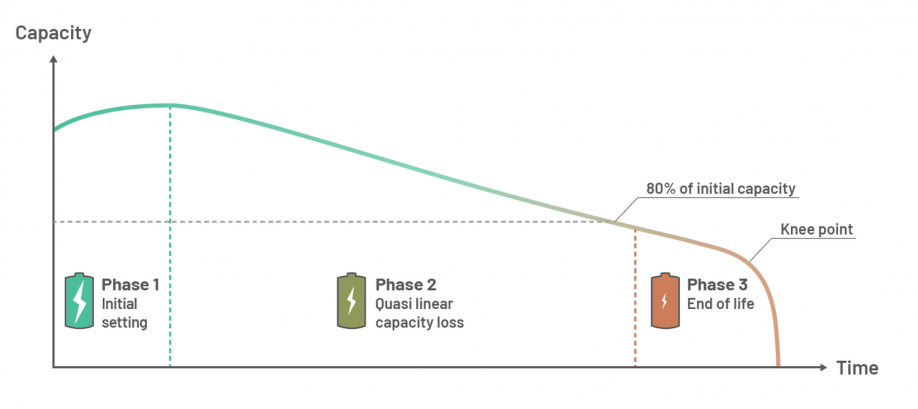

Looking at the aging of a lithium-ion battery, the aging trend can roughly be split into three phases, as illustrated in Figure 1:

Figure 1: Battery Aging - Typical Battery Capacity Lifecycle

- Initial settling. At the start of the battery’s life, different chemical processes settle into place. The result can actually increase the capacity, even though the battery is used. One reason for this increase can be the anode overhang effect. The anode overhang effect describes Lithium stored in the part of the anode that is slightly wider than the electrode, which does not directly take part in the chemical reactions. The anode overhang is a reversible aging effect.

- Quasi linear capacity loss. In the second phase there is a strong correlation between the capacity loss and usage of the battery. As a rule of thumb, the relationship between the two is more or less linear if the battery is utilized under more or less consistent operating conditions (not like home storage systems with summer-winter fluctuations).

- Knee-Point. The third phase starts at around 50-85 percent of the initial capacity, when the “knee-point” occurs. This marks a rapid decline in capacity over a few cycles, signaling the end of the battery’s life.

Internal resistance degradation

In contrast to capacity loss, the internal resistance of a battery increases over time, which conversely leads to power reduction. This is especially relevant for hybrid electric vehicles (HEV). Increasing internal resistance in an HEV means you cannot accelerate as fast as before and they reclaim less energy from braking. For stationary storage operators this means reduced efficiency and power capability.

What causes capacity loss and increased internal resistance?

The main cause of aging in lithium-ion batteries is the growth of the Surface Electrolyte Interphase (SEI). The SEI layer forms on the negative electrode during the first charging cycle, commonly referred to as the formation cycle. The SEI gets thicker over time and is mainly influenced by the electrolyte chemistry and mechanical stress of active materials. The SEI is typically formed on the anode, which is mostly made of graphite, sometimes mixed with silicon.

As the Surface Electrolyte Interphase grows it binds Lithium. Subsequently, less lithium-ions participate in the charging and discharging reactions and the battery capacity decreases. The lithium-ions also pass through the SEI layer when the battery is charged and discharged. The thicker the SEI, the harder it is for the ions to move through it. This is why internal resistance increases: the SEI grows as the battery ages.

In addition to the SEI growth there are numerous additional processes such as cracking and corrosion that influence battery aging, but we will cover those in a different article.

What accelerates battery aging?

Calendric aging

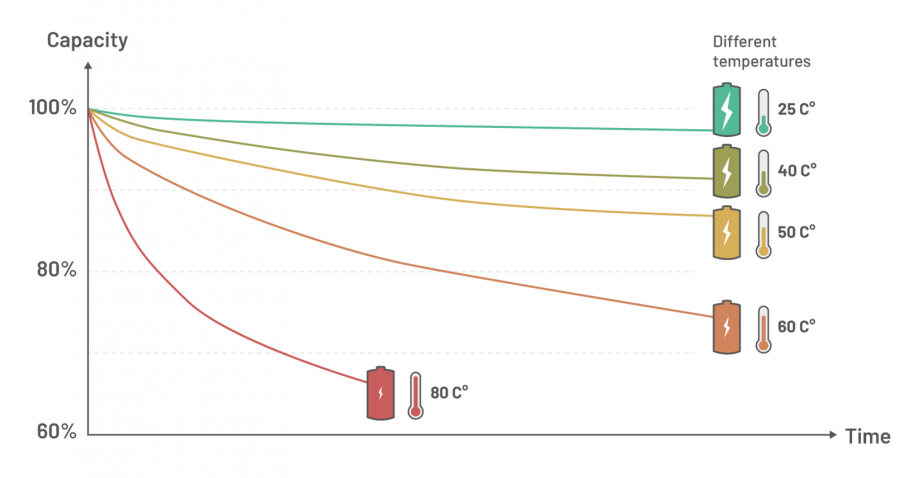

The main drivers of calendric aging are temperature and state of charge (SOC). Overall, at higher temperatures and SOCs batteries age faster. An average decrease of 10°C or 50°F can double a battery’s lifespan as illustrated in Figure 2. However, remember not to operate your batteries at too low temperatures because of lithium plaiting.

Figure 2: Comparison of Battery Aging Over Time at Different State of Charges and Temperatures

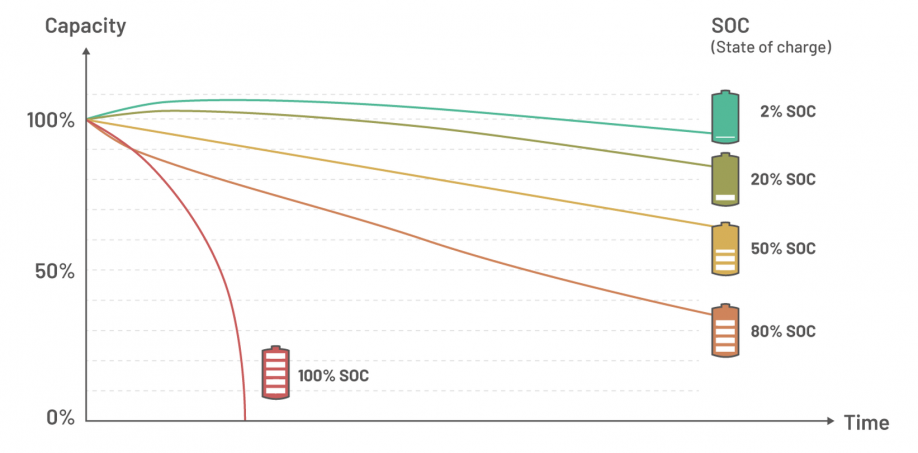

With higher SOCs – especially above 90 percent – battery aging increases rapidly as illustrated in Figure 3.3, 4, 5

Figure 3: Comparison of Battery Aging Over Time at Different States of Charge

Cyclic aging

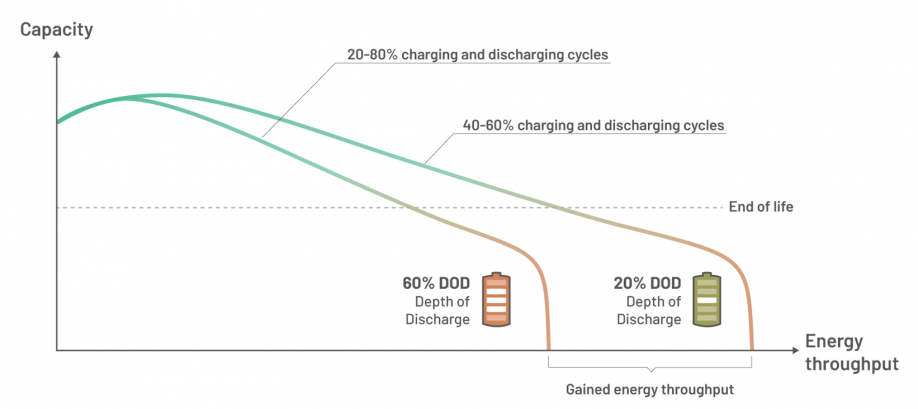

Cyclic aging is dominated by the energy throughput – the amount of energy that moves through the battery in a specific period of time – so the number of cycles plays a key role. However, small cycles are less harmful than big ones, as shown in Figure 4 (below). For example, three cycles with 20% depth of discharge (DOD) are less harmful compared to one cycle with 60% DOD, even though the total energy throughput is the same. This means the battery can sustain more cycles if the depth of discharge remains within a limited range.

Figure 4: Comparison of Sustained Cycles at Different Depths of Discharge

Additionally, the charging power influences the cyclic lifespan. A higher charging power or “fast charging” leads to increased aging. One reason is that charging a battery with high power raises the temperature, which leads to accelerated aging. Another reason is the increased risk of lithium plating.

Besides temperature, charging power, throughput, and depth of discharge, other effects such as phase shifts also accelerate battery aging. To get deeper insights ask-a-battery-expert[at]ACCURE.net

How can battery life be prolonged?

Using the insights about aging effects described above, intelligent operation strategies can be developed to easily prolong battery lifetime. Below are some recommendations for different applications. But the most important thing to remember is to only operate batteries within the given supplier boundaries. For example, do not charge batteries at temperatures that are too cold or too hot.

Tips to increase electric vehicles’ (EVs) battery life

It is especially important to operate electric vehicles in a lifetime-friendly way because one-third to half of the price of the EV is for the battery. Do not fully charge the battery directly after coming home when only a small part of the full range was driven. Keeping the battery fully charged accelerates aging so much that many car manufacturers require users to manually agree to charge the battery to 100 percent.

Some apps for electric vehicles offer smart features where the user enters the time when they need the car to be charged to avoid high SOCs for prolonged periods of time. For example, the user needs to get to work at 7 AM, then the car will start charging at 4am even if the car is plugged in earlier.

Finally, it’s recommended to only fast-charge the EV when needed. Fast charging uses high currents, which can result in high temperatures. Both are very costly in terms of aging.

Recommendations to increase battery lifespan for utility-scale battery energy storage systems

In the utility-scale storage sector battery aging is often overlooked. Most large-scale storage systems operate with software lacking functionality that comprehensively takes battery aging into account. For example, the software is designed to optimize the income generated but neglects the degradation costs of market participation.

To optimize the total cost of ownership (TCO) of utility-scale storage systems the degradation costs of different cycles must be factored in. With a digital twin, the costs of each cycle can be tracked and consolidated across systems to compare. With knowledge of both revenue and costs of market participation, the overall operation can be optimized to get the maximum total value of the asset.

Tips to reduce battery aging for home storage systems

Private households with rooftop photovoltaic (PV) systems use home battery energy storage systems to increase the self-consumption of power. These battery systems cost thousands and are increasingly in demand. Last year in the United States the residential storage market had two record quarters of 375 (Q2) and 400 (Q4) MWh installed.6 In Germany alone there’s an estimated 700,000 individual home storage systems.7

Most days, home battery systems store more energy than is consumed. As a result, the storage systems are cycled at high SOC ranges of 50 to 100 percent, which causes increased aging. To reduce the aging, system settings should delay charging the batteries until later in the day. This way the batteries spend less time overall at higher states of charge.

Additionally, predictive battery analytics can calculate a maximum needed SOC based on actual usage behavior over time. With this information, the system can be set to maintain the user-specific SOC to considerably reduce the average state of charge and prolong the lifetime.

Tips to extend battery life for consumer goods like e-bikes, smartphones, tablets, and laptops

One common mistake is keeping lithium-ion batteries fully charged most of the time. Here are recommendations to adjust the charging routine to extend the battery life and increase safety:

- Charge after getting up in the morning, while taking a shower or having breakfast instead of charging the device before going to bed. If the device is charged during the night, it will stay fully charged for an extended period of time, which should be avoided.

- For laptops or notebooks it’s recommended to limit the maximum state of charge to about 50 percent. Many laptop providers have implemented a feature that you can use to set a maximum threshold. Just don’t forget to turn up this threshold before you go off-grid for a longer time, such as if you are planning to travel. It is okay to have a higher SOC when needed. For safety reasons, we recommend low SOCs when taking your computer on an airplane.

- Other consumer goods such as electric toothbrushes, electric razors, or power tools should only be charged if the SOC is 20 percent or lower and not after every usage.

- Don’t fully charge electric bikes all the time. Instead, only do a full charge when the full capacity is needed to travel long distances. When storing e-bikes for extended periods of time, we recommend discharging the battery to 20-50 percent before mothballing it. Do not charge e-bikes outside when it is freezing, because this can cause lithium plating.

The New York City Fire Department has a helpful overview of safety tips for charging lithium-ion devices here.

Turn battery data into life-saving actions

How batteries are used and the conditions they operate under have a significant impact on aging. This means businesses that control operations and maintenance can prolong the battery lifetime with simple but intelligent adjustments. Every battery ages differently, which is why we recommend a battery business intelligence solution that analyzes operation data to help determine the safest and most profitable operating strategy for your specific situation. There is much more you can do to prolong the lifetime of batteries when you turn data into actions.

References

1 Amrita Dasgupta, Max Schoenfisch. Grid-Scale Storage Infrastructure deep dive, International Energy Association. Date of last revision: September 2022. Date retrieved: 8 March 2023 [https://www.iea.org/reports/grid-scale-storage]

2 Martin Placek. Metals & Electronics › Electronics, Different types of EV batteries' market share worldwide 2020-2050, statista. Date of last revision: 6 January 2023. Date retrieved: 8 March 2023 [https://www.statista.com/statistics/1248519/distribution-of-different-electric-vehicle-batteries-on-the-global-market/]

3 Peter Keil et al 2016. Calendar Aging of Lithium-Ion Batteries, Journal of The Electrochemical Society, Soc.163 A1872. Date retrieved: 3 April 2023 [https://iopscience.iop.org/article/10.1149/2.0411609jes]

4 Madeleine Ecker et al 2014. Calendar and cycle life study of Li(NiMnCo)O2-based 18650 lithium-ion batteries, Journal of Power Sources, Volume 248, Pages 839-851, ISSN 0378-7753. Date retrieved: 3 April 2023 [https://doi.org/10.1016/j.jpowsour.2013.09.143]

5 Georg Angenendt, Hendrik Axelsen, Sebastian Zurmühlen, 2018. PV Home Storage System (PV-HOST) Betriebsstrategien und Systemkonfigurationen für Batteriespeicher für Einfamilienhäuser mit Photovoltaikanlagen" : Bericht zum Teilvorhaben der RWTH Aachen : Abschlussbericht (German), ISEA, RWTH Aachen University. Date retrieved: 3 April 2023 [https://www.tib.eu/en/suchen/id/TIBKAT:1016723725/]

6 Q3 U.S. grid-scale energy storage market sets new record, Wood Mackenzie. Date of last revision: 15 December 2022. Date retrieved: 08 March 2023 [https://www.woodmac.com/press-releases/q3-us-grid-scale-energy-storage-market-sets-new-record/]

7 Sandra Enkhardt. 500.000 Photovoltaik-Heimspeicher mittlerweile in Deutschland installiert, PV Magazine. Date of last revision: 6 April 2022. Date retrieved: 8 March 2023 [https://www.pv-magazine.de/2022/04/06/500-000-photovoltaik-heimspeicher-mittlerweile-in-deutschland-installiert/]

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product