There has been a lot of discussion from students and instructors on SEI’s campus regarding lithium battery recycling. SEI’s Lab Manager and Instructor, Alex Jahp, was able to put together some information for our students and staff on the topic.

Lithium Ion Battery Recycling

Report from | Solar Energy International

There has been a lot of discussion from students and instructors on SEI’s campus regarding lithium battery recycling. SEI’s Lab Manager and Instructor, Alex Jahp, was able to put together some information for our students and staff on the topic. Alex began his solar career with SEI courses in 2015 and now, as the Paonia Lab Manager, we all benefit from his continual learning and thoughtful engagement with solar technology. This brief overview of the state of lithium (Li-ion) battery recycling, processes, and barriers to scaling will hopefully lead to more discussion of sustainability in solar and an improved understanding of how to manage the exponential impact of the human species.

State of Lithium Recycling

Li-ion battery recycling is vitally important to minimize mining in the energy transition and ensure the adequate availability of materials in the future. Much has been made of how the transition to renewable energy is not green because it will require substantial mining to supply the minerals to produce PV modules, batteries, wind turbines, etc. Concerns about trading one unsustainable behavior for another, i.e. fossil fuel extraction for rare earth mining, are legitimate, but the amount of materials needed and disruption required for renewable energy production pales in comparison per unit of energy produced compared with fossil fuel combustion. Coal power production requires 2,000 times more material input by weight than solar generation to produce the same amount of energy1.

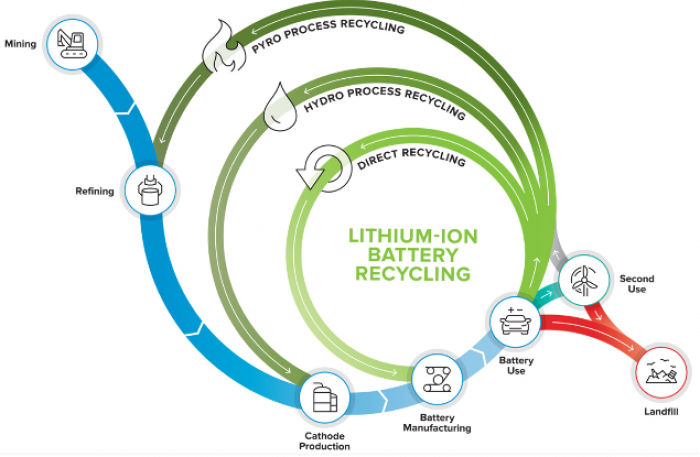

Currently, less than 1% of lithium that is used in batteries is recycled and consequently, less than 1% is included in new products2. Historically, the main objective of Li-ion battery recycling has been the recovery of cobalt, because of its high value. Everything else has been secondary. There is a range of Li-ion battery recycling processes with varying outcomes. Process components can be combined in different ways, depending on factors like quantity and characteristics of the material available, and the value of the materials that can be recovered3.

Pyro Process Recycling (smelting) – lowest rate of material recycling

Pyrometallurgy uses high temperatures to facilitate the oxidation and reduction reactions in which transition metals like Co and Ni are reduced from oxides to metals, and recovered in a mixed metal alloy. The metals can then be separated (by hydrometallurgy) and used to make new cathode material. Other materials including aluminum, anode, and electrolyte are oxidized in the smelter, supplying fuel for the process. The aluminum and lithium oxides end up in the slag and are not generally recovered3. While effective, this method typically only recovers 40 to 50 percent of the materials, excluding the graphite, aluminum, lithium, and plastic also found in batteries4.

Hydro Process Recycling (leaching) – medium rate of material recycling

Hydrometallurgy uses acids to dissolve the ions out of a solid like the cathode, producing a mixture of ionic species in the solution. These can be recovered by precipitation or solvent extraction and reacted with other recovered materials to produce new cathode material3. This process can be used to recover approximately 80-100% of materials when combined with direct recycling4.

Direct Recycling (physical deconstruction) – highest rate of material recycling

Direct recycling separates the different components of the black mass (active material powder from the shredding of cells) by physical processes, like gravity separation, which recover separated materials without causing chemical changes, enabling the recovery of cathode material that is reusable with minimal treatment.

Recycling Li-ion Batteries in North America

There is a lot to be explored here. Simply stating that recycling facilities exist does not mean that the problem is being properly addressed by the government or the private sector. There are many questions to consider: Are these facilities accessible for people working in small-scale energy storage or just large-scale Electric Vehicle (EV) manufacturers or utility storage? What is the cost of recycling a battery? How do we ship used Li-ion batteries? What is the cost of shipping? Is there any value returned to the person bringing in the battery? Can a facility handle all chemistries and formats?

Starting from the Beginning

The EPA recommends the following for recycling EV and Energy Storage (ES) batteries5:

- Automobile: Contact the automobile dealer, shop or salvage yard where the battery was purchased.

- Energy Storage: Contact the energy storage equipment manufacturer or company that installed the battery

Where might these batteries end up? According to USGS, about 25 companies in North America and Europe recycle Li-ion batteries or plan to do so6. Here are a few such companies:

Redwood Materials can process 6 GWh of end-of-life batteries, enough to build more than 60,000 EVs, each year. This quantity represents the majority of the Li-ion batteries recycled in North America today, and Redwood is ramping up their capacity in preparation for larger battery volumes as the first wave of EVs retire. Redwood recovers more than 95 percent of the metals (including nickel, cobalt, lithium, and copper) from these batteries and uses the metals to remanufacture anode and cathode components. Redwood then supplies these components back to U.S. battery cell manufacturers without the metals ever leaving the country. By 2025, Redwood Materials will ramp up copper foil anode and cathode production to 100 GWh annually – enough for 1 million EVs a year – representing the first time these critical materials have been manufactured in the U.S.

Li-Cycle is a Canadian lithium recycling company operating in the US with locations in New York and Arizona that can handle larger batteries including EV batteries. Li-Cycle states:

- All chemistries and formats of lithium-ion batteries are suitable for our technology

- Recover up to 95% of all constituent materials found in lithium-ion batteries.

- No production of landfill waste during the process.

Ascend Elements is currently building what is anticipated to be the largest Li-ion battery recycling facility in the U.S. Located in Georgia, the facility plans to return 100% of battery active materials back into the supply chain.

Barriers to Li-ion Battery Recycling

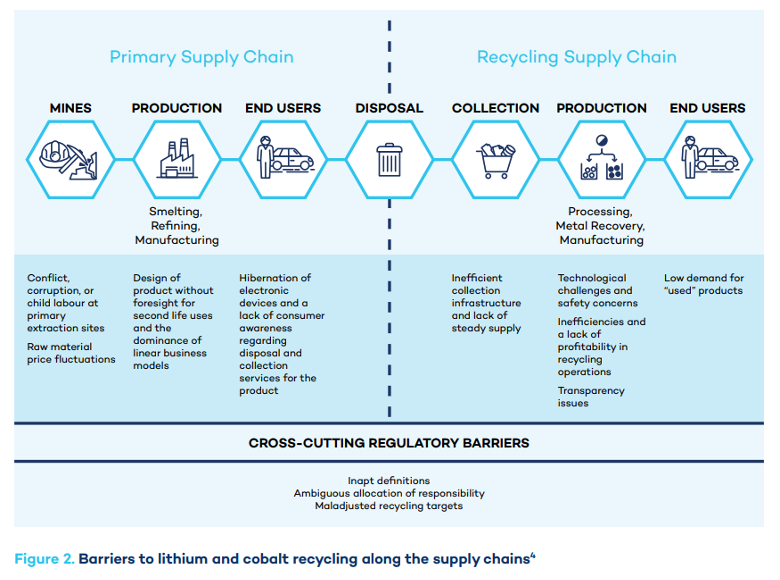

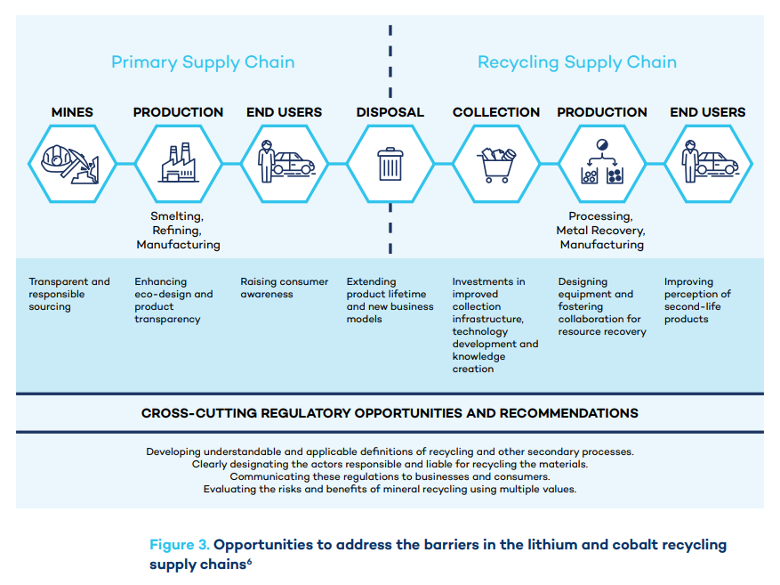

Barriers to recycling exist on both the primary material supply chain side and the recycling supply chain side. It seems like the largest issues are developing the waste diversion infrastructure and building facilities that can recycle material of sufficient quality to be used in new products; thus, closing the loop. Regulation is likely needed to make this happen.

Source: “Sustainability and Second Life: The case for cobalt and lithium recycling,” (Church & Wuennenberg, 2019)

Source: “Sustainability and Second Life: The case for cobalt and lithium recycling,” (Church & Wuennenberg, 2019)

In the Meantime…

Solar Forward endorses the adage, “reduce, then produce,” because it promotes the most cost-effective and reasonable measure for planning a switch to renewable generation: minimizing energy intensity. The most resonant part of this research and the ongoing Li-ion battery discussion among SEI’s faculty is about efficiency, lifestyle changes, and whether replacing a combustion engine with an electric vehicle really solves the problem of sustainability writ large.

It is entrenched doctrine in some circles of the renewable energy transition that batteries are the way and the light for making the switch from combustion. The push to electrify everything is laboring under the notion that the new load will be replaced with renewable energy as fossil fuel power is retired. How quickly and efficiently we can achieve that renewable energy deployment is the new goal line. It is only one facet of the issue with which people, societies grapple: As we find ways to break with old paradigms, are we trading them for more nuanced versions of exploitation instead of assessing lifestyle changes that would negate a purchase in the first place?

Do you have a Li-ion battery you want to recycle? Let us know how you do it, who do you call? Where do you send it and at what cost?

Do you work in the Li-ion battery industry? What do you recommend folks do with their Li-ion batteries at the end-of-life stage?

If you are a Solar Forward community partner, please share your thoughts on Li-ion battery recycling in the Resource Center Cyber Cafe. If you are not yet a Solar Forward community partner, then please reach out to ellen@solarenergy.org to find out more.

Sources

1 Bond, K. (2021, May 10). Mineral constraints for transition overstated by IEA. Carbon Tracker Initiative.

2 Hund, K., La Porta, D., Fabregas, T. P., Laing, T., & Drexhage, J. (2020). Minerals for Climate Action: The Mineral Intensity of the Clean Energy Transition. World Bank Group.

3 Gaines, L. (2018). Lithium-ion battery recycling processes: Research towards a sustainable course. 17(C).

4 Church, C., & Wuennenberg, L. (2019). Sustainability and Second Life: The case for cobalt and lithium recycling. 68.

5 US EPA, O. (2019, May 16). Used Lithium-Ion Batteries [Overviews and Factsheets].

6 USGS. (2022). Mineral Commodity Summaries 2022 (p. 206). U.S. Geological Survey.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product