Depending on the time the energy needs to be stored, and the number of according charges and discharges, different technologies are to be considered – but all of them have one thing in common: they essentially depend on vacuum technology.

Vacuum for Energy Storage - Solutions for Stationary Flywheel Systems

Vacuum for Energy Storage - Solutions for Stationary Flywheel Systems

Article from | Pfeiffer Vacuum

An ever increasing demand for quickly available and cost effective energy worldwide stands opposite the issues of climate change and growing environmental awareness in our society. As a consequence, the demand for improved technologies in the field of energy storage, especially with regard to regenerative energies, is ever rising. This development is a major booster for developing new technologies and innovative production processes in this area. The diversity of the particular applications thereby lets new technologies face various challenges. Depending on the time the energy needs to be stored, and the number of according charges and discharges, different technologies are to be considered – but all of them have one thing in common: they essentially depend on vacuum technology.

Vacuum for flywheel technology

The short-term storage of energy has shortly been revolutionized by an innovative technology: mechanical flywheel energy storages. They are used as stationary or mobile systems in different applications. Part two of the series on “vacuum for energy storage” by Pfeiffer Vacuum focuses on stationary flywheel systems. Stationary flywheel systems are, for example, used as Uninterruptible Power Supply (UPS) in data storage centers and hospitals. Moreover, grid balancing tasks – which become more and more important due to an increased use of solar and wind energy – can also be supported by flywheel systems. A long lifetime even when facing many load cycles as well as the possibility to provide the stored energy instantly when needed make them the ideal choice for this application. Although the basic principle of saving energy through a rotating mass can easily be understood, designing an efficient and safe system is quite challenging.

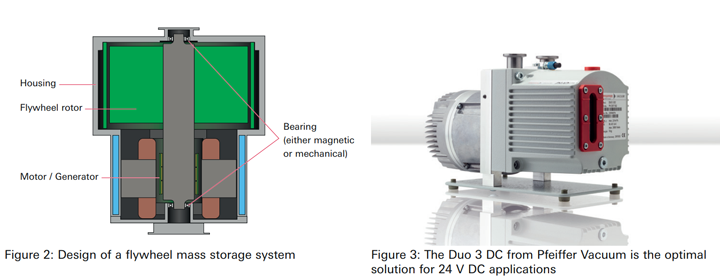

Design of a flywheel mass storage

One of the main components of a flywheel is its rotor. It is usually either made of tempering steel or fiber-reinforced synthetics. The choice of the right material is demanding. Requirements are a high specific tensile strength to withstand the enormous forces as well as a low elastic modulus to keep the tight tolerances and to allow a high energy density, just to name a few. The rotational speed of the rotor can be several ten thousands of rotations per minute – some models even reach up to ninety thousand rotations per minute. Therewith, a high energy density can be reached.

The bearing of the rotor is either mechanical or magnetic and has to be designed with minimal friction. The housing has to act as containment in case of a failure. The gap between the rotor and the housing needs to be large enough to allow the extension of the rotor due to dynamic and thermal stress (see Fig 2).

Its electrical equipment ensures the conversion of energy: While charging, the flywheel acts as a motor that is driven by electrical energy. While discharging, the flywheel constitutes a generator that produces electricity.

Vacuum ensures efficiency

To ensure the efficiency of a flywheel as an energy storage device, the constant losses through friction have to be reduced to a minimum. To do so, the flywheel housing is evacuated with vacuum pumps. Typical targeted pressures are 1·10-1 hPa down to 1·10-3 hPa or even less. As a result, both heat generation and energy losses are drastically reduced. As there is a constant gas load due to small leakages and outgassing of the rotor, each flywheel system is equipped with vacuum pumps. Because of their high achievable pressure combined with reliable technology at low cost, dual stage rotary vane pumps are optimal for this application. In systems with comparably high gas load or targeted pressures lower than 1·10-3 hPa, additional vacuum equipment is necessary. Therefore, turbopumps are usually added to the system. They offer good performance at a low level of power consumption.

The vacuum pumps included in the flywheel system have to fulfill high demands: The most important ones are small dimensions combined with a good final pressure and low power consumption.

Optimal solution from Pfeiffer Vacuum

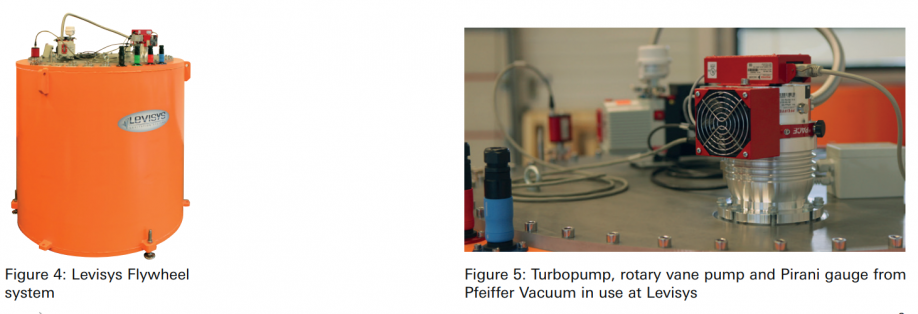

With its dual stage rotary vane pumps of the DuoLine and its popular HiPace turbopumps, Pfeiffer Vacuum offers ideal solutions that match the requirements of flywheel mass storage systems. Among them, the special edition of the Duo 3 with an innovative DC drive is outstanding on the market. The pump can be supplied with 24 V DC and is able to work in a temperature range from -20 °C up to +60 °C, which makes it ideal for mobile flywheel applications and thus directly dedicated to this field. Furthermore, Pfeiffer Vacuum pumps and gauges are used in flywheel systems worldwide.

Pioneer of energy storage relies on Pfeiffer Vacuum

The French pioneer in the development of energy storage, Levisys, has trusted in Pfeiffer Vacuum solutions for its experiments and developments right from its beginning. The start-up company developed and implemented the first 10 kW stationary flywheel storage system at the production site of Engie Ineo, a French major player in electric engineering, in the city of Toulouse. The company has established a so-called SmartGrid in which a stationary flywheel system is used to equalize deviations in the power supply. In this way, the new storage method for electricity contributes to the regular energy supply of the production site. It complements the lithium-ion batteries used for energy storage so far. After the first test phase, nine more stationary flywheel storage systems will be added to reach a capacity of 100 kWh. The stationary flywheel mass storage systems from Levisys use rotary vane pumps of the DuoLine, HiPace turbopumps as well as vacuum gauges to generate and measure the needed vacuum conditions. The demands set on the vacuum equipment are high: It has to work reliably, be compact as the space inside the stationary flywheel systems is limited and furthermore must have a low power input. With its high reliability and quality, the Pfeiffer Vacuum equipment was the perfect solution for the specific requirements of Levisys and represents further possibilities for vacuum solutions.

The advantages of the particular products at a glance:

Rotary vane pump Duo 1.6

- Pumping speed of 1.25 to 11 m3 /h

- Optional maintenance-free magnetic coupling allows for individual process integration

- High operating reliability through hydraulically controlled high vacuum safety valve

- Convenient system integration due to small footprint and optimal arrangement of vacuum connections

- Integrated oil return connection for easier retrofit

- Energy-efficient single-phase electric motors for low power consumption

- Single-phase motor plus integrated safety and gas ballast valve

Turbopump HiPace 300

- Pumping speeds of up to 260 l/s for N2

- Maximum reliability in a compact design

- High pumping speed and maximum compression for all gases

- Semi S2 and UL/CSA certification

- Ideal for industry and research

- Integrated drive electronics, suitable for industrial environment protection class IP54

- Continuous monitoring of operating data

Vacuum gauges of the DigiLine

- Pressure range 5·10-10 to 2,000 hPa covers the entire vacuum range

- Digital signal transmission for error-free communication with a PC or PLC

- Suitable for integration into automated applications with HiPace turbopumps

- Optional fieldbus interfaces or analog output with two set points as options available

- Transmission of numerical pressure values eliminates the need to deal with characteristics and recalculations

- Protection class IP54 and M12 connector assemblies for reliable operation in heavy-duty environments

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product