If you anticipate your solar company to thrive for the next two decades, its time to begin thinking about the responsibility we have to ensure modules stay out of our nations landfills.

Can Solar Panels Be Recycled?

Can Solar Panels Be Recycled?

Tom Schoder | CivicSolar, Inc

Anyone who works in the solar industry is intimately aware of the benefits solar energy provides to communities nationwide. Clean, renewable energy bolsters local economies, helps reduce greenhouse gas emissions, and requires little maintenance over the lifespan of the investment compared to other forms of energy generation. What many industry professionals are unaware of is what pros and cons exist for solar modules at the end of their useful life.

At of the beginning of 2018, the United States had 53GW of solar capacity deployed. Assuming the average wattage of each solar module installed was 250W, the total weight of all panels deployed equates to 89 billion pounds or 44.5 million tons. Put differently, that’s the equivalent weight of 122 Empire State Buildings in solar modules installed across the country.

For an industry that prides itself on sustainability, there must be a focus on recycling at the end of a solar project’s lifespan so that landfills don’t overflow with panels. As things currently stand, solar panel recycling is not a huge issue in the US because a vast majority of installations have occurred in the past ten years; nevertheless, the market need for developed recyclers will only increase over time. In fact, a 2016 study by the International Renewable Energy Agency (IRENA) estimates the recyclable materials in old solar modules will be worth $15 billion in recoverable assets by the year 2050.

Source: GreenMatch.com

How are they recycled?

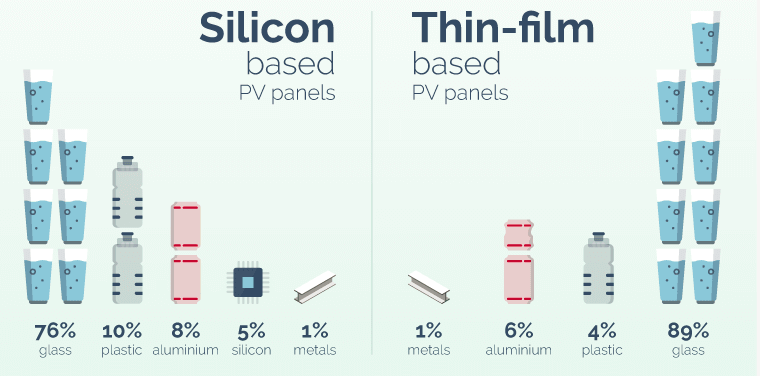

So can solar panels be recycled? The short answer is yes. Silicon solar modules are primarily composed of glass, plastic, and aluminum: three materials that are recycled in mass quantities.

Despite the recyclability of the modules, the process in which materials are separated can be tedious and requires advanced machinery. Here are the main steps involved in successfully recycling a silicon module:

- Removing the aluminum frame (100% reusable)

- Separating the glass along a conveyor belt (95% reusable)

- Thermal processing at 500 degrees Celsius

- This allows for the evaporation of small plastic components and allows the cells to be easier separated.

- Etching away silicon wafers and smelting them into reusable slabs (85% reusable)

Because many European nations installed greater PV capacities in the 1990s, a solar PV module recycling market is steadily maturing. The Waste Electrical and Electronic Equipment Directive (WEEE) of the European Union helped found a member-based organization called PV Cycle to build out a robust recycling infrastructure. Here’s a look inside one of their plants:

Thus, the US market has plenty to learn from their European counterparts when it comes to PV module recycling. While Washington became the first state to pass a solar product stewardship law last year, more states will have to join this initiative to place greater pressure on manufacturers to develop recycling programs.

It may seem easy to kick the can down the road when it comes to PV module recycling. After all, these solar panels often last well beyond their 25-year lifespan and continue to negate greenhouse gas emissions. Nevertheless, the long-term success of our industry relies on successfully recovering the raw materials that produce solar modules. If you anticipate your solar company to thrive for the next two decades, it’s time to begin thinking about the responsibility we have to ensure modules stay out of our nation’s landfills.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (1)

Featured Product