PV systems must not only be tested to proper standards and methodologies, but the design data must also be applied consistently and accurately to prevent failures costly to customers and harmful to the PV industry.

Principles of Wind Loading for PV Arrays

Contributed by | DCE Solar

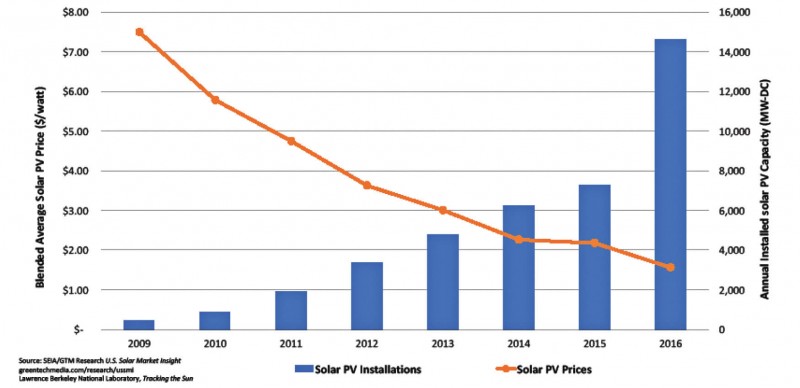

The Solar Industry in the US is growing by leaps and bounds. In 2016 alone over 14.8 GW of solar was installed, nearly doubling the amount installed in 2015. This growth is fueled largely by decreases in the installed price of solar, which dropped by 29% in 2016, and cumulatively has decreased 67% over the last 5 years.

While this price drop is seen across all market segments, it was led by reductions in hardware costs. With a new solar system coming online every 84 seconds and tremendous cost pressure on both manufacturers and installers, extraordinary effort is now needed to put measures in place to prevent dangerous compromises from being made.

PV systems must not only be tested to proper standards and methodologies, but the design data must also be applied consistently and accurately to prevent failures costly to customers and harmful to the PV industry.

Due to the multiple complexities of a solar design, there are many factors to be considered from electrical, mechanical, and structural engineering as well as proper installation guidelines. This article will focus specifically on wind loading considerations for solar arrays on low-slope roofs.

Background

For many years, there was little direction on how proper wind loads should be established for rooftop solar systems. Designers and structural engineers were left with trying to appropriately apply building design standards to solar panel structures with very little resemblance to the buildings or scenarios that codes like ASCE 7 were designed for.

The solar industry follows wind load provisions that are currently promulgated by the American Society for Civil Engineers (ACSE), based in Reston, VA. The latest standard is the 2013 ASCE/SEI 7-10. But that standard relates more to buildings than to solar arrays, several manufacturers complain. In a 2012 statement to Renewable Energy World, SunLink CEO Christopher Tilley said, “while there are established snow and seismic load standards that can be applied to PV systems in a fairly straightforward manner, there is very little guidance on wind loads. Engineers and permitting officials have therefore been left with the choice of applying the building code in ways not intended or accepting designs based on wind tunnel testing without a standard means to validate the testing approach or results. Neither method assures that appropriate wind design values are used.”

One of the first efforts to demonstrate a code compliant methodology for calculating wind loads was done by Colleen O’Brian and Stephen Barkaszi in a Solar ABC’s publication titled Wind Load Calculations for PV Arrays. This publication provided not only theoretical guidance but several actual calculations for sample roof mounted PV arrays. At the time, they advocated the use of the MWFRS methodology of ASCE 7-05 which uses the solar structure as the main wind force resisting system, but can be too conservative for a ballasted system that is often not a contiguous structure.

In 2011, Dr. Gregory Kopp, Dr. Joe Maffei, and Christopher Tilly published “Rooftop Solar Arrays and Wind Loading, A Primer on Using Wind Tunnel Testing as a Basis for Code Compliant Design per ASCE7.” This was a landmark effort that documented for the first time how wind loads could properly be measured and established for rooftop solar systems. This guide recommended that ASCE 7 Method 3 be utilized whereas wind loads are established by racking specific testing done at qualified Boundary Layer Wind Tunnels. The authors also advocate using a Components and Cladding approach to correctly account for building impact on the wind loads and proper area averaging.

In 2012 the Structural Engineers Association of California (SEAOC) issued the PV-1 and PV-2 reports, giving formal recommendations for the first time on how solar PV systems should be designed to resist Seismic and Wind Loads respectively. These reports represent a momentous step of progress by establishing a prescriptive design method similar to the language of ASCE 7 but specific to solar. The standard also contains guidelines for wind tunnel testing as well as a step by step procedure for how to establish wind loads. Intended to be a direct complement to the figures in ASCE 7-10, SEAOC provides a figure for determining nominal net pressure coefficients on a solar array with provision for different tilt angles. The authors of SEAOC understood that companies would pursue wind tunnel testing specific to their racking systems, so they prescribed that wind tunnel coefficients could not be decreased beyond 50% without an independent review by a qualified reviewer.

While SEAOC provided the groundwork for a design methodology and established some guidelines for how wind loads should be established, there were still large areas of uncertainties on how the methodology should be applied to various mounting system configurations and specific building applications. In a paper published by the Journal for Structural Engineering in 2014, Joe Maffei, Karl Telleen, Rob Ward, Gregory Kopp, and Andreas Schellenburg purposed to provide recommendations and a practical approach for the application of methodologies established in ASCE 7-10 and SEAOC. This paper outlines a step by step methodology to apply design wind pressures and perform a structural analysis of the system considering both maximum individual panel forces and shared loads across connected panel arrays. This effort also took aim at one of the largest areas of uncertainty in performing structural analysis on a low slope roof system: how should the tributary area for structural analysis be established. This also has major implications because with the Components and Cladding methodology, the tributary area determines the wind coefficient applied to determine the design wind pressure. The authors developed an analytical model to examine the highly nonlinear stiffness that develops as multiple panels attempt to lift and distribute forces on the array. The authors also briefly outlined some empirical tests used to calibrate their structural simulation model.

Alternatively, the efforts outlined above to define methodologies and standards to allow for ICC code compliant structural design to be performed, UL2703 was introduced in an effort to establish certifications and ratings for mounting systems, and mimic the matching panel standards in UL1703. UL2703 was originally released as an Outline for Investigation in 2011, and ratified as a binding standard in July 2016. This standard outlines guidelines and tests to verify that mounting systems perform adequately with regard to electrical bonding, corrosion, and mechanical loading. While UL2703 does not endeavor to establish what the wind loads on a structure should be, it outlines a mechanical load test to simulate loads that the structure would receive from wind, snow, and dead loads, and a minimum rating that the structure must pass.

While it is certainly helpful and desirable to have safety criteria and certifications to guarantee the safety of mounting systems, the standard suffers from both vagueness scope and immaturity. There are a wide range of mounting systems for various applications and the standard attempts to apply generically to all of them. While this has been improved as new versions have been released, there are still several significant gaps, and interpretation of the standard by the various Nationally Recognized Testing Laboratories (NRTL’s) can vary substantially. Some of these challenges have been raised by various industry members: The Underwriters Laboratory, based in Northbrook, Ill., nominally covered wind load for PV installations in the 2015 version of UL 2703, but is also criticized for falling short. “UL 2703 has been good for the industry but it is not an absolute standard. Having a true code in place would level the playing field by weeding out the companies that don’t address important safety and performance factors, such as wind and snow load testing, corrosion testing and fire resistance,” said John Klinkman, VP of engineering at Applied Energy Technologies, in Clinton Township, MI.

Future Developments

Members of both ASCE and SEAOC committees are continuing to work to bring definition to the proper design for the PV industry. ASCE 7-16 has provisions for solar specifically, and the SEAOC committee is working on an update to the PV1 and PV2 reports. While significant work has been done as outlined above, there are still several gaping holes that need to be filled by future code efforts.

1. REQUIREMENTS FOR PROPER WIND TUNNEL TESTING

Thanks to the aforementioned works, it is well established in the PV industry that wind loads must be established using boundary layer wind tunnel testing performed with geometries specific to the panel and mounting system being used. Unfortunately, there are still a few gaps in how proper wind tunnel evaluation should be performed that can lead to non-conservative and possibly catastrophic results. This was mentioned in a Structural Journal article where is was recommended that:

“ASCE 49 was not developed with product testing in mind. This has led to lack of clarity on how to conduct boundary layer wind tunnel studies for roof-mounted arrays. The additional requirements outlined in SEAOC-PV2 partially resolve this; however, there are still differences of opinion in how to conduct such studies. We advocate for approaches that are the same as how the provisions for the low-rise Components and Cladding roof loads in ASCE 7 were developed in order to maintain risk consistency.”

1.1 THEORETICAL MINIMUM FOR GCP

Should be around 50% of SEAOC values. Reducing coefficients below this threshold yields values on the same order of magnitude as the uncertainty of the measurement, which is not prudent.

1.2 PROPER MODEL SCALE

“In order for the results of a wind tunnel study to be applicable to a wide range of installation conditions, the building model must to be large enough to generate the proper wind flow environment on the roof. Typically, this is done with 1:25 to 1:50 scale building models that are at approximately four times the model height in length to capture cornering vortices and flow reattachment that governs roof zoning, as the roof zoning indicated in ASCE 7 for components and cladding is not applicable to tilted solar arrays on flat roofs. The wind tunnel study should also provide recommendations for setback distances from larger rooftop equipment, penthouses, clerestories and other building features.”

Tests conducted at much smaller scales can result in inaccuracy.

1.3 DATA SAMPLING AND ANALYSIS TECHNIQUES

SEAOC-PV2 provides additional guidance on data sampling approaches, although it does not prescribe them fully. Of particular importance is the analysis method, which requires careful treatment of the statistical analysis of the peak pressures used in design. Both ASCE 7 and ASCE 49 are silent on the precise requirements even though this is an area of significant importance which can put some systems at risk.

2. DESIGN CONSIDERATIONS FOR PROPER APPLICATION OF BLWT DATA

2.1 HOW TO ESTABLISH LOAD SHARING

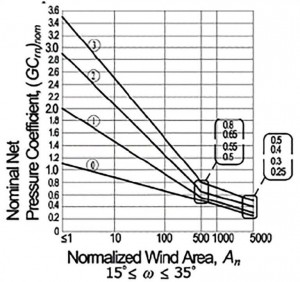

Figure 2: Normalized Wind Area vs. Nominal Net Pressure Coefficient

Because the greater the load shared area the lower the wind coefficient, there is a temptation in the industry to use unrealistic or inflated load shared values in an attempt to generate lower wind loads and reduce ballast demand. The graph below illustrates this relationship between the load sharing area (normalized wind area) and the wind load (nominal net pressure coefficient). As An increases, GCm values decrease rapidly. While SEAOC PV2 has a sample calculation of load sharing, and the authors of the Journal article elaborated with a specific analysis routine and model, there is currently no established procedure in industry for how the load sharing calculations should be performed, and what empirical testing or analysis must be performed to confirm the effective wind area being used. It is imperative that designers and structural engineers are using both analysis and testing to examine the complex non-linear stiffness of panel arrays to generate accurate load sharing values.

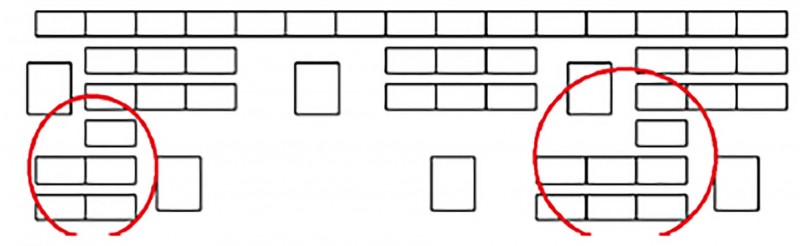

Additionally, the load sharing value should vary based upon the intricacies of each rooftop layout. For example, smaller less connected parts of the array will certainly have a diminished ability to engage the stiffness of adjacent modules and therefore will have a lower shared area value. Simply applying a maximum load sharing value to all panels in an array can result in grossly non-conservative wind load values. This is particularly true for arrays with large gaps or panel “fingers”. It is the opinion of the authors that the ideal scenario would be to establish different load sharing values for each panel in an array, and to determine the wind loading individually for all panels in the array based upon these values.

2.2 HOW TO APPROPRIATELY APPLY LOAD SHARING WITH BALLAST AND ATTACHMENT PLACEMENT

Once the load sharing value has been determined and the correct wind loads have been calculated, ballast weight or mechanical attachments must be placed in order to resist the horizontal and vertical components of the wind load. This is another area where there is little to no industry guidance on how these restraints should be placed in the design. Typically, there is a practical limit to how much ballast can be placed on a single panel, both from a roof capacity limitation as well as room in the racking system to accommodate the typical concrete ballast blocks. Manufactures will often place ballast blocks where space is available, rather than giving proper consideration as to whether a ballast block place at one panel can actually be “felt” at the panel where the restraint is required.

Attachments represent an even more complicated arrangement. Typical mechanical attachments have allowable capacities between 200-1000 pounds of force. When an attachment is placed on the array, however, it is not as simple as decreasing the ballast demand by the value of the attachment. First, the panel shared value for the location that the attachment is being placed at must be determined, and then it can be determined how much load can be distributed based upon the available capacity.

Often, if an attachment is placed at the corners or edges of an array, the attachment force can legitimately only be distributed to a small number of adjoining panels, therefore the available capacity of the attachment must be de-rated to account the impact of load sharing. For this reason, it is recommended that attachments never be placed on the extreme outside panels in an array as it is rare that the full capacity of the attachment can be utilized at these locations. Once an attachment has been placed, any ballast present needs to be redistributed to account for the impact of the attachment.

2.3 DESIGNS USING THE MODULE AS A STRUCTURAL MEMBER:

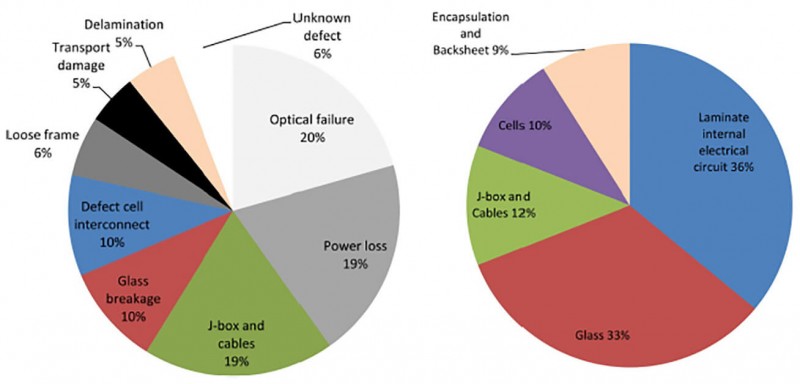

One of the most realistic threats to the solar industry is the failure of solar power plants to perform up to their rated expectations. As the industry matures, the 20 and 25 rear expected rates of returns and often not measuring up to promise. In a report for the Solar America Board for Codes and Standards (see Resources), Mani Tamizh-Mani and Joseph Kuitche note: “Technology risk—the concern that a technology will underperform (durability) or become obsolete prematurely (reliability)—is one of the major barriers to PV diffusion and project financing.” In effect, more than 95% of fielded PV modules need to meet or exceed manufacturers’ product and power warranty terms to satisfy investors. (as quoted in SolarPro http://solarprofessional.com/articles/products-equipment/modules/fielded-pv-module-reliabilty-and-durability)

Figure 5.2: Field study of PV module failures found for various PV modules of 21 manufactures installed in the field for 8 years [redrawn from DeGraaffll]. The rate is given relative to the total number of failures. Approximately 2% of the entire fleet are predicted to fail after 11-12 years (do not meet the manufacturer’s warranty).

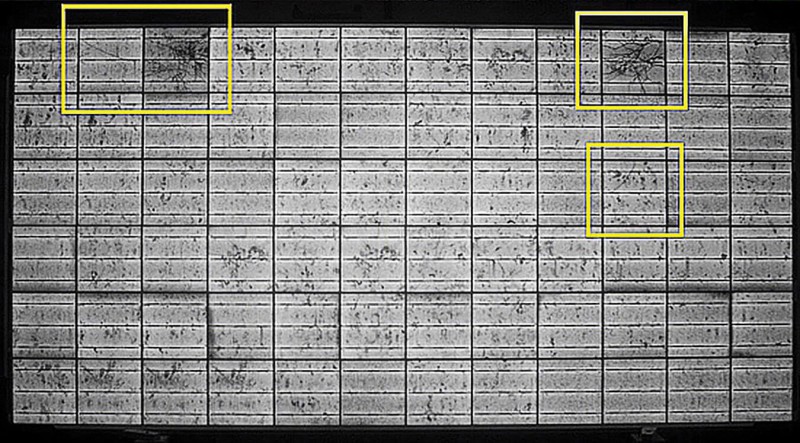

Why is this important? NREL found that module cracking is significant issue to performance degradation. One of their primary recommendations was to increase the stiffness of the module, and recognized that the racking plays a big role in this. The module laminate, module frame, and racking need to be considered together as a unified system. Most designs merely support the modules at 4 points near the edges. Cost effective designs to reduce module ending [failure] may be best implemented during module installation in the field.

https://www.nrel.gov/pv/assets/pdfs/2015_pvmrw_04_gabor.pdf

While not called out explicitly, racking designs that use the module as a structural member place a substantial amount of stress on the modules and cells and will certainly result in increased module cracking.

Figure 6: Cracked PV Cells (http://solarprofessional.com/articles/products-equipment/modules/fielded-pvmodule-reliabilty-and-durability/page/0/5)

In addition to the potential for module damage and significant performance degradation (find infographic with figure), using the module as a structural member can result in significant inconsistencies in the array stiffness.

For example, a module with a thinner aluminum frame and glass will have markedly less structural stiffness than that of a module with a more robust frame and thicker glass.

These differences along with the module weight would have to be incorporated in a testing or analysis program in order to accurately determine the correct load shared value.

Conclusions

Until standards are published and these areas clarified, the industry must attempt to self-police to protect itself. To do this, developers and EPC’s need to ask questions of the manufacturers that are providing their products and engineering.

http://solarbuildermag.com/featured/solar-rooftop-ballast-installation-system-best-practices/

“You need experts in how to use that spreadsheet to generate ballast drawings. You need executives who make smart decisions about the risks they will take and not take based on the data they have,” Nicolaou says. “And that’s just wind.”

Nicolaou thinks the solution starts with developers and EPCs asking the right questions. “If the codes and standards don’t exist, then developers and EPCs need to hammer the racking companies on what testing they are doing beyond UL and wind, and that’s how the industry can self-police.

Who is running the wind program? Who is doing the ballasting? What is the methodology? What are your safety factors? What are the design guidelines like? Installers need to ask more questions.”

SAMPLE QUESTIONS TO ASK RACKING MANUFACTURERS / EQUIPMENT SUPPLIERS

1. What percentage of SEAOC wind coefficients are you using your design?

At DCE Solar, we follow the 50% recommended threshold because it is scientifically proven to offer a smart mix of performance and value. Anything less than 30% may be compromising quality and safety in the name of price.

2. What scale is your wind tunnel testing done at?

This truly matters because you want to apply a scale that actually translates to the size and scope of your equipment being tested. As well, using an accredited facility that understands the forces you’re expecting to measure, and can help interpret results (positive or negative) is a secondary benefit. DCE Solar’s racking equipment was tested at the University of Western Ontario Boundary Layer Wind Tunnel Laboratory at 1:30 scale, under the direction of Dr. Greg Kopp. This is the same tunnel used for ASCE 7-16 testing.

3. Has the design approached used on YOUR project been vetted by third party BLWT expert?

As with any testing in any field, a neutral third-party evaluation without bias is the most certain way to ensure accurate, reliable results. DCE Solar’s findings have all been reviewed by Dr. Joe Maffei, who chaired the SEAOC PV-1 and PV-2 committees, along with Dr. David Banks of CCP, who did the wind tunnel testing for the SEAOC PV-2 Standard.

4. How was the array stiffness / load sharing value been determined?

Simply, you’ll want to make sure that the final analysis of any test is supported by the actual findings, and is not a misinterpretation of facts that could result in performance challenges.

DCE Solar’s findings were the results of extensive empirical testing using both deflection and stress as failure criteria. We then matched these results in a Finite Element Analysis Computational Model to determine stiffness and load sharing ability in all directions.

5. Does the panel shared value vary for differing array conditions?

Yes, the panel shared value varies based on how well the panels are connected to each other within an array. For instance, A corner panel should receive the least load shared value, and a center panel should receive the max.

6. Is the panel being used for load sharing?

While the weight of the panel is certainly a consideration, top-quality racking systems will not rely upon the panel for any structural connection. This is because PV panels frames are structurally different, can be fragile, and more prone to breaking under certain load cases rather than being supported with high-strength steel.

Racking that can self-contain the module load requirements are more effectively insulated from external stresses i.e. wind, snow and seismic condition failures.

As the industry continues to evolve, definitive industry guidelines will most certainly take root. Presently, the industry and those who work in it have the unique ability to lead this movement by adopting best-practice principles ahead of any mandate, demonstrating a desire to support a certain level of safety.

Choosing to work with companies that exemplify or exceed recommended principles is a proactive way to protect clients and establish a level of operation that is less likely to be challenged by future compliance issues.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product