Algae converts at a very high efficiency into biocrude, as it has lots of caloric value and happens to have the same molecular structure as petroleum. So out of all the whole biomass sources, algae is probably the most efficiently converted to biocrude.

Algae to Biofuel Technology

Riggs Eckelberry | OriginOil, Inc.

Can you give me some background on how this technology was developed?

OriginOil has always been a technology company, but initially we targeted the end to end process – both growth and harvesting.

OriginOil has always been a technology company, but initially we targeted the end to end process – both growth and harvesting.

Then, in late 2008 my Nicholas Eckelberry invented the process we later called Single Step Extraction™, and we realized that while there are many growth technologies, there are few harvesting solutions, and ours was really promising.

We spent a year and a half getting the basic design together, and then a company called MBD Technology came along from Australia. They were funded to make a LOT of algae, and they realized that they had to have a scalable way to get the algae out of the water and ruptured for downstream use, and they basically persuaded us to go into the field with them.

We started working with them in June 2010, and by December they had pronounced our technology a success, and early in the following year they ordered progressively larger systems, which we have been delivering since then.

With MBD, we have attained a scale appropriate to modular algae production. In other words, you’re not going to have one giant algae pond, you’ll have a series of smaller ones, and our harvesters (at 100K gallons/day) are appropriately sized to reach service one typical pond.

What kind of barriers had development of this kind of technology faced before, and how were they overcome?

The algae industry has been favored by very high priced products (nutritional and pharmaceutical applications) and so there wasn’t the drive to really cut energy and operating costs.

With the new huge, lower-cost markets, you have to have low-cost production; and if it’s for fuel, you can’t expend more energy than you get out of it. This really brings to the forefront the biggest challenge in algae: the fact that it lives in a tremendous amount of water – a water-algae ratio as great as 1000 to 1.

So a new technology was needed to get the algae out of the water economically, at large scale and with very low energy expense. Also, the process had to be chemical-free so as to enable re-use of the water.

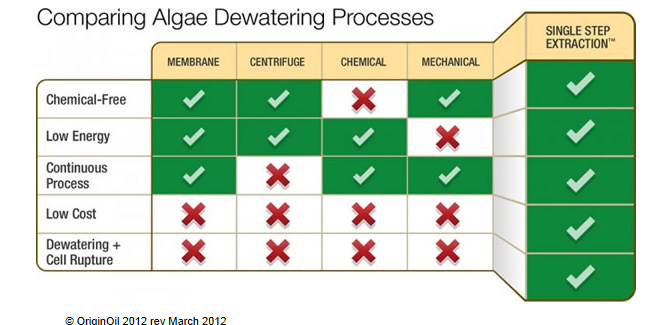

OriginOil’s process satisfies all these requirements. There is no other process that does – (see the comparative matrix below)

Can you walk me through the process of how oil is extracted from algae?

Right now, fuel is being made from the vegetable oil portion of algae (for example, the big sale of algae biofuel to the US Navy by Solazyme in Dec 2011), but extracting the whole algae from the water is better.

You then process the whole algae concentrate into fuel or other products.

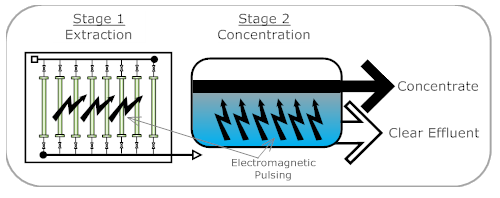

Our role is simple: first we run the extraction stage, and then the concentration stage. This is our Solids Out of Solution™ or SOS process.

(Please see the figure below).

- In the extraction stage, we use our Single Step Extraction™ process to make the algae (or other organic solid) come out of solution. Now it’s solids floating around in the water.

(Imagine that you have made a pot of coffee, but now you want to pull the coffee back out. In this step, we are making the coffee particles stick to each other so they become visible in the water.)

- In the concentration stage, we use a flotation process to push all of the solids to the surface where they are easily raked off.

The water below is now relatively clear and can be reused immediately (in the case of algae production) or can be further processed to ground water quality (as in the case of oil and gas water cleanup).

(In the coffee analogy, you now push all the coffee solids to the surface, and you’re left with clear water below.)

It’s chemical-free, very low-energy, and can be operated in a continuous flow mode.

Now what you have coming out of this is a sludge or concentrate that is still 80-90% water. But now it’s economical to use centrifuges and filters to remove the rest of the water, if desired.

To make biocrude from algae, you actually want to keep a certain amount of water. So you would get the concentrate to about 40% solids and then you would put it through a hydroconversion process of some kind. For example, a process like CRI’s which creates true distillates from biomass.

What grade of crude is the resulting end product?

You get biocrude which is functionally identical to light sweet crude oil.

Usage of water and contamination of water have been issues since the fracking boom began. How much water is used in algae harvesting versus fracking?

Algae is an aquatic species, so great quantities of water are used. However, this water can be waste water, or brackish, or ocean water. So there isn’t a comparison with frack water, which must be fresh.

What are the advantages of algae versus other biofuels?

Algae converts at a very high efficiency into biocrude, as it has lots of caloric value and happens to have the same molecular structure as petroleum. So out of all the whole biomass sources, algae is probably the most efficiently converted to biocrude.

Can you give an update on the use of algae in carbon capture and storage? Is this what the Australia and other overseas projects are focused on?

Yes, carbon capture and storage (or carbon capture and re-use) are strong in other countries and in Australia, very strong. The scale of the power station site operated by our partner MBD Energy is being dramatically expanded.

Our project in France is being driven directly by an energy regulation for large buildings, RT 2020.

As a pure technology company, we are less constrained by location, so we can adapt easily to where algae is being supported as it develops the scale needed to succeed.

Can you predict a timeline for the development and implementation of Algae biofuel production over the next 5 years or so?

We are seeing complete acceptance and commercialization of algae for high-end applications such as nutrition and cosmetics. However that relies on older processing technology. The bigger market for chemicals and fuels needs new techniques now proven in pilot stages. The next stage is scale-up, which will take the remainder of the decade.

What do governing bodies need to do to support this advancement and what parts of the world are at the forefront?

Primary need is for R&D support, and for large entities (such as the military) to guarantee offtakes. Despite congressional opposition, this is moving forward in the USA, mainly due to the courage and commitment of the Dept. of Defense. Australia is probably the furthest along as it has a carbon tax that can be applies to algae development.

We also see growing momentum in Japan, due to the problems there with nuclear and with toxins. Algae production both remediates toxins and produces fuel and chemicals. We expect to see a great deal of activity from Japan.

Additionally, Thailand and other Asian countries are showing strong momentum. East Asia in general, including China, are showing great promise. Finally, India, with Reliance Industries at the forefront, has momentum.

Riggs Eckelberry is OriginOil, Inc.’s President and CEO. In January of 2011, Riggs Eckelberry was named to the Advisory Board of the National Algae Association for his leadership in the field of algal biofuels technology. Mr. Eckelberry is a member of the Algal Biomass Organization, is a Corporate Advisor to the Intergovernmental Renewable Energy Organization (IREO), and in September 2009, OriginOil presented the industry’s first-ever comprehensive algae production model, developed with the Idaho National Laboratory (INL) of the Department of Energy. OriginOil is publicly-traded: OOIL.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product