We've cobbled together some great factoids from the Apricus website to create this overview of Solar Thermal systems. Why are we not using this technology on every home that is exposed to the sun?

Solar Thermal 101

Contributed by | Apricus Solar

Water heating and space heating accounts for more than 60% of the average households utility bill. Installing a solar water heating system can offset 60-80% of your annual water heating energy costs and reduce your carbon footprint.

How Does It Work?

The Apricus evacuated tube solar collector utilizes energy from the sun to provide hot water and space heating for homes and businesses.

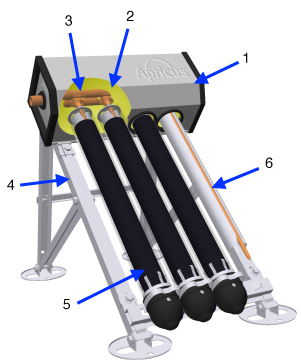

Solar Collector Parts

Solar Collector Parts

- Collector manifold

- Glass wool insulation

- Copper header pipe (liquid flow)

- Stainless steel mounting frame

- Evacuated tube (solar absorber)

- Heat transfer fin and heat pipe

Collector Operation

Step 1: Sunlight is absorbed inside the evacuated tube causing it to heat up.

Step 2: The heat pipe inside the tube carries this thermal energy up to the manifold box.

Step 3: Fluid circulates from the storage tank up through to the header pipe and extracts the energy from the hot heat pipe tips.

Step 4: The newly heated fluid circulates back to the storage tank where it can be used and the cycle begins again.

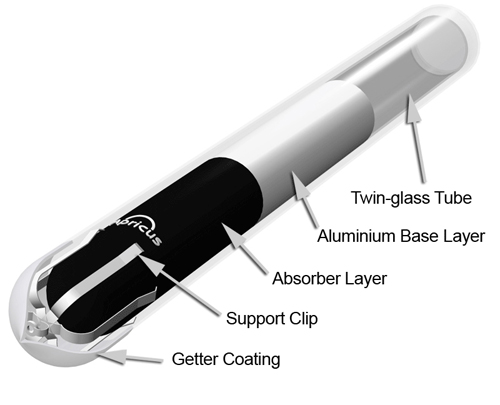

What is an Evacuated Tube?

Evacuated tubes absorb solar energy and convert it into heat for use in water heating. There are several types of evacuated tubes used in solar thermal collectors. Apricus collectors use the most common "twin-glass tube". This type of tube is chosen for its reliability, performance and cost effectiveness.

What is a Heat Pipe?

Heat pipes might seem like a new concept, but you are probably using them everyday and don't even know it. Laptop computers often using small heat pipes to conduct heat away from the CPU, and air-conditioning system commonly use heat pipes for heat conduction.

The principle behind heat pipe's operation is actually very simple.

.png)

Structure and Principle

The heat pipe is hollow with the space inside evacuated, much the same as the solar tube. In this case insulation is not the goal, but rather to alter the state of the liquid inside. Inside the heat pipe is a small quantity of purified water and some special additives. At sea level water boils at 100oC (212oF), but if you climb to the top of a mountain the boiling temperature will be less than 100oC (212oF). This is due to the difference in air pressure.

Based on this principle of water boiling at a lower temperature with decreased air pressure, by evacuating the heat pipe, we can achieve the same result. The heat pipes used in AP solar collectors have a boiling point of only 30oC (86oF). So when the heat pipe is heated above 30oC (86oF) the water vaporizes. This vapor rapidly rises to the top of the heat pipe transferring heat. As the heat is lost at the condenser (top), the vapor condenses to form a liquid (water) and returns to the bottom of the heat pipe to once again repeat the process.

At room temperature the water forms a small ball, much like mercury does when poured out on a flat surface at room temperature. When the heat pipe is shaken, the ball of water can be heard rattling inside. Although it is just water, it sounds like a piece of metal rattling inside.

This explanation makes heat pipes sound very simple. A hollow copper pipe with a little bit of water inside, and the air sucked out! Correct, but in order to achieve this result more than 20 manufacturing procedures are required and with strict quality control.

Quality Control

Material quality and cleaning is extremely important to the creation of a good quality heat pipe. If there are any impurities inside the heat pipe it will effect the performance. The purity of the copper itself must also be very high, containing only trace amounts of oxygen and other elements. If the copper contains too much oxygen or other elements, they will leach out into the vacuum forming a pocket of air in the top of the heat pipe. This has the effect of moving the heat pipe's hottest point (of the heat condenser end) downward away from the condenser. This is obviously detrimental to performance, hence the need to use only very high purity copper.

Often heat pipes use a wick or capillary system to aid the flow of the liquid, but for the heat pipes used in Apricus solar collectors no such system is required as the interior surface of the copper is extremely smooth, allowing efficient flow of the liquid back to the bottom. Also Apricus heat pipes are not installed horizontally. Heat pipes can be designed to transfer heat horizontally, but the cost is much higher.

The heat pipe used in Apricus solar collectors comprises two copper components, the shaft and the condenser. Prior to evacuation, the condenser is brazed to the shaft. Note that the condenser has a much larger diameter than the shaft, this is to provide a large surface area over which heat transfer to the header can occur. The copper used is oxygen free copper, thus ensuring excellent life span and performance.

Each heat pipe is tested for heat transfer performance and exposed to 250oC (482oF) temperatures prior to being approved for use. For this reason the copper heat pipes are relatively soft. Heat pipes that are very stiff have not been exposed to such stringent quality testing, and may form an air pocket in the top over time, thus greatly reducing heat transfer performance.

Freeze Protection

Even though the heat pipe is a vacuum and the boiling point has been reduced to only 25-30oC (86oF), the freezing point is still the same as water at sea level, 0oC (32oF). Because the heat pipe is located within the evacuated glass tube, brief overnight temperatures as low as -20oC (14oF) will not cause the heat pipe to freeze. Plain water heat pipes will be damaged by repeated freezing. The water used in Apricus heat pipes still freezes in cold conditions, but it freezes in a controlled way that does not cause swelling of the copper pipe.

Collector Efficiency

The efficiency of a solar collector is constantly changing throughout the day, factors such as ambient temperature, fluid temperature, insolation levels play a role in dictating how well a collector converts the sun’s energy into usable heat. Most certifications publish information that will allow you to determine a collectors performance.

Solar water heater performance is often presented as a graph, or set of three performance variables. Values may be provided based on gross area, aperture area or absorber area. In Europe, aperture or absorber is often used, in the US, gross area is often used. It doesn't really matter which value is used, as long as you use the correct value. ie. Don't use absorber area when using performance values based on gross area.

To adjust from one to the other, multiply by the size difference. ie. If aperature area = 32.05 ft2 & gross area = 44.76 ft2 then (44.76/32.05) = 1.39), so multiply the performance factorsby 1.83 to convert from gross to absorber.

The three performance variables for the Apricus solar collector as provided by the Solar Rating & Certification Corporation (SRCC Certificate #2007033A) are as follows (for imperial calculations):

| Conversion Factor - η0 | First Order Loss - a1 | Second Order Loss - a2 | |

| Aperature Area | 0.634 | 0.33076 | 0.00051 |

| Gross Area | 0.456 | 0.23796 | 0.00037 |

As well as the three performance variables show above, insolation level (G) in Btu/ft2, ambient temperatures (Ta) and average manifold temperature (Tm) must be known. These values give the value X, also known as the fluid parameter, used in the formula below.

(other slightly different forms of this formula are used, but provide the same result)

How to use the formula:

Based on the ambient temperature, average manifold temperature and insolation level, first calculate the value for X.

Eg. At midday; ambient temperature of 77oF (25oC); average water temp [(Tinlet+Texit)/2] of 122°F (50oC); insolation level of 252Btu/ft2 (800Watts/m2).

x = (122-77)/252 = 0.1785

Now enter all the values into the formula:

h(x) = 0.634 - (0.33076*0.1785) - (0.00051*252*.17852)

h(x) = 0.634 - 0.0590 - 0.0040 = 0.571

The solar conversion efficiency for that specific point in time and set of environmental conditions is 57.1% based on aperture area. That is: 57.1% of the energy provided by the sun is actually used to heat the water.

Below is a first order graph showing the performance curves for the Apricus solar collector based on the inlet fluid parameter.

.jpg)

Most domestic water heating applications occur in the range of 0.2-0.4 with higher temperature applications happening further to the right on the graph.

One factor which is not considered in the straight performance calculations outlined above, is the affect of transversal or longitudinal IAM values (Incidence Angle Modifier). Considering IAM is important, as for Apricus solar collectors it accounts for as much as an additional 25% in total daily heat output values.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product