During a vacation trip to the Disney World, I saw the Exxon-Mobile energy presentation. The presentation includes a portion in the form of the Jeopardy game. For the final question in the Jeopardy game, the answer is "The solution to the future energy need." The correct question is "What is brain power?"

James Lau | LAUSDEO Inc

Introduction

During a vacation trip to the Disney World, I saw the Exxon-Mobile energy presentation. The presentation includes a portion in the form of the Jeopardy game. For the final question in the Jeopardy game, the answer is “The solution to the future energy need.” The correct question is “What is brain power?”

Human have been endowed with the ability to resolve many problems. In this wonderful world plenty of supply is available for human to enjoy life if adequate management effort is made. The world’s energy supply cannot run out.

This writing is going to identify a procedure to secure low cost energy for human consumption for as long as the sun shines. The brain power of the human is the critical factor to implement the solution. This analysis also indicated that OTEC power as part of the solar power is sufficient.

Hydrocarbon from fossil fuel is at this time the dominant form of primary energy source. The total carbon used in fossil fuel in the world is about 9 billion tons a year, generating about 29 billion tons of carbon dioxide, a well known green house gas every year. For the world population of 6.5 billion people, the average carbon use is about 1.4 ton per person.

Technical Summary

For those people that do not want to get into the details, the basic assumptions are summarized here.

1. Energy from the sun in being stored in the ocean at a rate more than two thousand times the world wide energy need for all human activities.

2. Energy stored in the ocean has been identified (in 1881) as a potential source for human energy need. Tropical areas provide the best locations. Some technology to use this energy source has been developed.

3. Effective method to use the ocean thermal energy has been identified by LAUSDEO Inc. This completely renewable method can provide electricity at 2 cent per kilowatt hour.

4. The cost for conducting initial experimental indoor technology demonstration is less than 50 thousand USD. Ocean model demonstration for OTEC should cost less than 1 million USD. Continuing expansion can be funded from profit of the operation. There is absolutely no need for subsidy of any kind after technology demonstration.

Development Steps

The eventual deployment of millions of semi-submerged OTEC plants must follow a viable development path. The following are reasonable steps.

- More complete feasibility investigation. Room size demonstration plant.

- Construct and test proof of concept floating OTEC plant.

- Construct cost competitive, effective OTEC plants.

- Design cost efficient OTEC plant fabrication, deployment and operation procedures.

- Install and operate OTEC generators.

After the first three steps have been completed, there would be no need for outside funding. The profit from the operation would be able to carry the project.

1. The cost to achieve the first step is estimated to be 50,000 USD.

The room size model may use copper tubing as heat exchangers elements. Both the high and low temperature heat exchangers will have 36 coils of 50 feet length ½ inch diameter flexible copper tubing. The 36 coils will be arranged as six groups of six coils arranged in hexagonal shape. Each 24 loop coil would be about 8 inches in diameter. Soldering will be the method for joining all the coils in the heat exchangers. The working fluid will be distributed to all heat exchanger coils through a distribution network. After the working fluid reached the desired temperature, a collection network will direct the working fluid to the out put side of the heat exchanger. The top (high temperature) heat exchanger will accept the working fluid in liquid form at the bottom. The vaporized working fluid will exit from the top and enter the top of the electricity generator turbine. After passing through the turbine and generate electricity, the working fluid would move down toward the lower (low temperature) heat exchanger. The working fluid will condense into liquid. Pump will be used to moved the condensed working fluid toward the top heat exchanger. The height of both the top and bottom heat exchanger will be about 20 inches.

The complete model should have slight positive buoyancy so that an anchor at the bottom of the tank will hold the OTEC model in place. Other details of this one kilowatt generator will be specified later.

The hot and cold zone will be created with heater and cooler. Ice placed into water will cause some water to reach 4 degrees Celsius and sink to the bottom of the container. After enough ice has been used, the bottom of the container will be at 4 degrees Celsius. Heater place near the top can then be used to heat the water near the top. The ocean top temperature may reach 30 degrees Celsius. The water tank use for OTEC feasibility demonstration should have the top temperature of 30 degrees Celsius. It may be easier to keep the demonstration tank bottom temperature at 4 degrees Celsius, but the required depth in actual ocean would be about 1000 meters. My preference is to use bottom heat exchanger temperature of 10 degrees Celsius. I think the trade off of 500 meter length (by a factor of 2) with 6 degrees Celsius (by a factor of 0.25) temperature difference is favorable. To get the bottom at 10 degrees Celsius, some stirring or even bottom heating may be necessary. There will be no net energy gain for the room size demonstration unit because the water temperature profile is created with external energy.

During the time of room size model construction, detail design for the ocean model should be made. It is most desirable that additional funds can be used for detail design. The detail design effort should include contacts to potential material and component suppliers. The design shall incorporate materials from identified available sources. Effort to get proper authorization by relevant political entities may be made. Contacts to the governments of USA, State of Hawaii and states around the Gulf of Mexico should be attempted. Formal patent application can wait until the room size demonstration and detail design is well underway.

2. The cost for making the small scale ocean model is estimated at 1 million USD.

The first model to be installed in the ocean will be able to generate about 300 kilowatt of power. The power generated is the net energy gain because the desired temperature profile is provided by the ocean at no operational and energy cost to the operator.

Both the top and bottom heat exchanger will have 216 tube elements. Extruded aluminum joined together with total length up to 30 meters may be used. The working fluid phase changes will be like the room size model. The main fluid transport tube diameter of about 35 cm should be sufficient. The complete structure should have slight positive buoyancy so that an anchor is able to keep the OTEC plant in place and away from severe weather damage.

Public announcement of the success may be made during this stage. Additional capital may be secured with the publicity.

3. The cost for making the operational model is estimated at 12 million dollars

The operational model will be able to generate 12 megawatt of power. The 40 fold generator capacity increase is achieved by 40 fold size increase. Instead of the 216 heat exchanger tube elements (for each of top and bottom heat exchanger) there will be 7776 tube elements. The 36 fold increase in the number of tube combined with doubling the tube length would increase the heat exchange capability by a factor of more than 40.

The main flow tube of slightly less than 2.4 meter in diameter is chosen to fit the containerize transportation system. OTEC plant sections can be made at less than 12 meter length almost anywhere in the world. The sections will be assembled at the floating assembly facility and towed to the operating location using OTEC power. Hawaii in the middle of the Pacific Ocean is a good OTEC plant assembly place.

The cost of generating one kwh of electricity is from about two cents to 10 cents. Previously, the environmentally undesirable methods (nuclear, coal) are cheaper than the more environmentally friendly method (natural gas). With the trading of carbon emission allowance, OTEC operator may completely recover the investment by trading carbon allowance alone.

At 2 cents per kwh, an OTEC plant of 12 megawatt capacity can generate 1.0 x 108 kwh of electricity worth 2,000,000 USD. The 12 million USD investment can be recovered in 6 years. With the expected OTEC plant life of 50 years, the net income would be more than 100,000,000 USD.

If we apply electricity at the higher price (6 cents per kwh) for the clean energy, the yearly income from the generated electricity would be 6,000,000 USD. The investment recovery period will be two years. The net OTEC plant life time income would be more than 300,000,000 USD.

With profit margin like this additional OTEC plant can be funded by the profit without the need for any government subsidy or additional investor. We should be ready to pay heavy tax.

Global Energy Need

Human society needs to use energy. There are many accessible/available energy sources. The required energy also needs to be in the appropriate form. The required energy may be converted from one form to another. Due to the fact that the conversion required is usually not perfectly efficient, the energy wasted during conversion and transmission may be much higher than the energy actually used for the desired goal. The diverse forms of useful energy and the lack of perfect energy conversions makes calculating the total energy requirement difficult. People talk about energy need, but there is no simple inclusive system to determine the amount of worldwide energy need.

At the most basic level, human needs to eat to survive. Food is known to provide energy so that warm blood creature like human can maintain proper body temperature and do work. It is worthwhile to mention that doing work usually also keep the body warm. A reasonable estimate is an adult need about 2000 (kilo) calories a day to live. The 2000 calories do not include the energy used in cooking the food. For people living in cold environment, additional energy from food has been used. Warm clothing or heated dwelling can substitute for some of the energy provided by food. It is very rare to use other forms of energy to substitute for food. Even though food is one form of essential energy, most discussions about energy are about other non-nutritional forms so that the rest of the discussions here will exclude food.

Hydrocarbon (or just carbon) in the form of wood, coal, natural gas or oil is now the most important energy source. In the 20th century, human also learned to use nuclear power. It is possible to argue that the only significant remaining available energy source is solar energy. The familiar solar energy forms are photovoltaic, hydroelectric (dam), wind, tide, ocean current and OTEC.

Electricity is a convenient form of energy that can operate many devices. Electric power lines and wireless devices allowed electric energy to be used in diverse locations. Electricity should not be regarded as primary energy source because electricity is generated by using up some other form of stored energy such as hydrocarbon (coal, oil, natural gas). The efficiency for converting hydrocarbon chemical energy to electrical energy is usually below 40 %. If we want to calculate the energy requirement, the difference between using the chemical energy content of the hydrocarbon or the using converted electric energy will be a factor of two or more. Like electricity, hydrogen should not be regarded as primary because available hydrogen is usually obtained by converting hydrogen containing material into hydrogen using other forms of energy. Electrolysis decomposing water into hydrogen and oxygen is a good example.

The two most important forms of fossil hydrocarbon are crude oil and coal. Each barrel of oil contains about 5100 MJ (mega-joules) of energy. Each ton of coal contains about 22,000 MJ of energy. Oil is used to power most consumer transportation devices (cars, trucks) and the price is carefully monitored by many people in the world. In 2008, the price for a barrel of crude oil fluctuates from 40 USD to 147 USD. The cost for each MJ (or kwh which is equal to 3.6 MJ-mega-joule) of energy from oil is therefore in the range of 0.8 cents (0.008 USD, 0.036 USD/kwh) to 2.8 cents (0.029 USD, 0.1 USD/kwh). Most consumers are less sensitive to the price of coal, but the price of coal generally stays below 100 USD per ton. The cost for each MJ of energy from coal is between 0.25 to 0.45 cents (0.0025 to 0.0045 USD, 0.009 to 0.016 USD/kwh using price of between 55 and 100 USD per ton). It should obvious why most of the electricity generated in USA uses coal as the primary energy source. Coal is much more cost effective. Because coal fired electricity generation plant conversion efficiency is only about 40 %, the actual coal generated electricity fuel cost is from 2 to 4 cents per kwh.

I am not yet able to find a reliable estimate of the total world wide electricity generation capacity. I am using 1.4 x 1014 kwh (kilo-watt-hour) as my estimate. Since the energy conversion efficiency for most hydrocarbon electric generating plant is below 40 %, the chemical energy of the hydrocarbon material used to generate its portion of the electricity (probably 40 %) is estimated to be more than 1014 kwh.

I am not yet able to compile the quantity of oil used for transportation, space heating and other purposes. I am also not able to find the energy provided by all other sources. I am using 2.5 x 1014 kwh as the total world wide energy need a year. With 6 billion (6 x 109) people on earth, the average energy need is about 40,000 kwh per person per year. Using the fact that there are 8,760 hours in a year, the average power consumption rate is about 4600 watt (11,000 kilo-calories). Energy provided by food is about 2 % of the energy necessary for all other applications.

Actually, there is another energy problem on earth that is far greater than the above mentioned human need. If we separated the surface of the earth into two regions, below and above 30 degree latitude, these two regions will be approximately equal in area. The region below 30 degree latitude will intercept about 61 percent of the sunlight. The region above 30 degree latitude will intercept about 39 percent of the sunlight. Even though the earth have very uniform surface temperature the black body radiation from these two regions are still different, the ratio is about 53 to 47 percent. To achieve the nearly uniform temperature distribution as indicated by the black body radiation ratio, energy equivalent to 8 percent of the sunlight energy need to move from the low latitude region to the high latitude region. Since human energy need is about 1 in 5000 parts of the sunlight energy, this energy transfer need is about 400 times the human energy need. This greater energy transfer problem has already been solved by ocean and atmospheric circulation. There is no need for human to worry about this problem.

Ocean Thermal Energy

For obtaining energy to meet human need, it is not necessary to search outside of the earth. Each year, solar radiation provided the earth with about 5 x 10 21 BTU of energy. This quantity is about equivalent to 1.4 x 10 18 KWH (kilowatt hour). About 32% of the direct solar radiation is immediately reflected back to space. Most of the absorbed energy is eventually radiated back into space with the characteristic black body temperature of about 15 degree Celsius. A very small fraction of the energy (less than 0.1 %) is converted to coal, crude oil and other form and stored for a period of more than 100 years. The short term stored energy available before black body radiation back into space is mostly in the form of temperature change (increase, 43% of the energy) and water vapor evaporation (23%). It is estimated that about two percent of the solar radiation energy has been converted to wind energy. Technology to extract energy from the wind and ocean is at the threshold of able to supply the energy need of the whole world.

The electricity need for the world is about 1.4 x 10 14 KWH a year. The electricity need is about 0.01 percent of the solar radiation energy. Generated electricity represented the most important form of economically significant human energy need. It is also possible to convert electrical energy into the proper form to provide human with almost all energy need. Total absorbed solar radiation is about 5,000 times the world energy need. Using the estimate that forty percent of the solar radiation energy has been converted to ocean thermal energy, the ability to use 0.03 percent of the ocean thermal energy would be sufficient to provide all the electricity need.

In tropical area, ocean surface temperature is likely to reach 25 degrees Celsius or higher. At the depth of 500 meter, the temperature is 10 degrees Celsius. At even greater depth (1,000 meter), the temperature is 4 degrees Celsius, the maximum density temperature. The available thermal energy for each square kilometer (to 500 meter depth) is roughly equivalent to the energy of 250 meter of water at a temperature difference of 15 degrees Celsius. The value is

(250)(100)(1000)(100)(1000)(100)(15)

= (3.75)(10 15 ) (calories)

= (1.57) (10 16 ) Joules

= (4.3)(10 9 ) KWH

Each Square kilometer of ocean may receive a maximum of (1.35)(10 9 ) watts of energy. Using 8 hours [(2.88)(10 4 ) seconds] as the equivalent time during each day that maximum solar input is possible, the possible maximum daily energy input is about (3.9)(10 13 ) Joules. The available heat content of the ocean surface (down to 500 meter depth) is equivalent of more than 400 days of deposited solar energy. The heat content of the ocean to 1000 meter depth is equivalent to 1000 days of deposited solar energy. For each square kilometer of the tropical ocean, the stored thermal energy is about (3.9X1016 ) Joules, or 9.2 Megaton of TNT. The energy stored in 10 square kilometer of the tropical ocean is greater than the energy of any hydrogen bomb ever made. The ocean is actually a much greater energy reservoir then the oil or coal deposit for the world. The energy is continuously replenished by the sun. As long as the earth stay in orbit around the sun and the solar radiation stay at close to the current level, the energy is available.

Earth is the planet with the smallest day/night temperature difference in the solar system. The average day time temperature is about 295 K. The night time average temperature is about 275K. Ocean containing water, a material with very high heat capacity, is the critical factor for temperature stability.

Area near the equator received so much energy from the sun that it is necessary to move some warm water toward the north and south poles to increase the area that is able to radiate at higher rate. Radiation in area near the poles would make the poles much colder (both day and night) if the warmer water from the equator is not available.

In addition to water, the atmosphere (wind and water vapor transport) also help to make the world temperature stable. The natural water and wind circulation already provide human living on earth with much more environmental control energy that all human technology can hope to achieve. Since the natural energy is so dominant, human directed adjustment in the form of OTEC can do little harm.

Ocean Thermal Energy Conversion Today

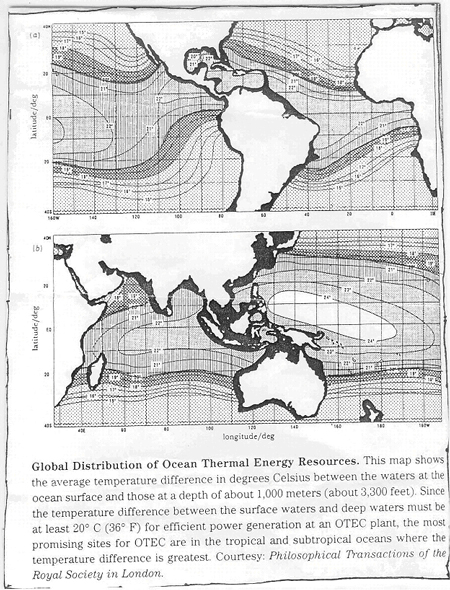

The father of the OTEC concept, French physicist and engineer Arsene d’Arsonval first proposed in 1881 that the temperature difference in seawater could be used to provide useful energy. The following page (originally from The Royal Society in London) is the Global Distribution of Ocean Thermal Energy Resources. The Best place is Micronesia in western Pacific Ocean. For citizen of USA, this location is very convenient because the islands in the area are under USA trust. The distance to Japan is about 1000 miles.

As energy price rose and technology improved during the 1970s, France, Germany, Japan the Netherlands and the United States became increasingly interested in OTEC power generation.

There are three existing types of OTEC concepts: open cycle, closed cycle and hybrid. Closed-cycle plants circulate a working fluid in a closed system, heating it with warm water, flashing it to vapor, routing the vapor through a turbine, and then condensing it with cold seawater. Open-cycle plants flash the warm seawater to steam and use the steam to vaporize a working fluid in a closed system. Hybrid plants flash the warm seawater to steam and use that steam to vaporize a working fluid in a closed system.

For more detail information please refer to the www.nelha.gov/otec website. I regard the project conducted by the Pacific International Center for High Technology Research in Honolulu, Hawaii (with government funding) as representative of the current open cycle OTEC technology. The system is able to generate 210 Kilowatt of gross power, but 170 Kilowatt is required to pump seawater and operate the system. There is also effort to include closed cycle investigation at the same NELHA (Natural Energy Laboratory of Hawaii Authority) site.

It is my opinion that the close cycle is the superior concept for ocean installation. Instead of using compact size heat exchanger that make ocean water (both warm and cold) forced circulation necessary, the large heat exchanger should spread out in the ocean connecting the warm and cold water region. There is apparently no significant US government funded (multimillion yearly budget) OTEC research in 2008. I think the reason is simply lack of understanding. All previous design concepts have been fatally inefficient.

It should be possible to build OTEC generator that can last for 50 years. If the investment cost can be recovered in less than ten years, which is likely the necessary condition to set up OTEC projects, for the rest of the time OTEC is operational the profit for the investor will be high. There should be no need for government subsidy or special tax arrangement. Government funding to initiate the project is acceptable.

The cost of building 12 MW OTEC plant is on the order of 10 million dollars. Setting up efficient OTEC plant production facility probably will cost another 25 million dollars. For the initial feasibility demonstration, a 100 KW OTEC plant at the cost of less than one million USD should be sufficient. A 12 MW power plant operating for 8,350 hours a year can generate 1 x 10 8 KWH (kilo-Watt-hour) of power a year. The total world wide demand for power can be satisfied with 2 million OTEC plant of this size. One square mile of tropical ocean can have 25 OTEC plants. 100,000 square miles of ocean would be sufficient.

In the following page is a map of OTEC resource.

Proposed Ocean Thermal Energy Conversion Plant

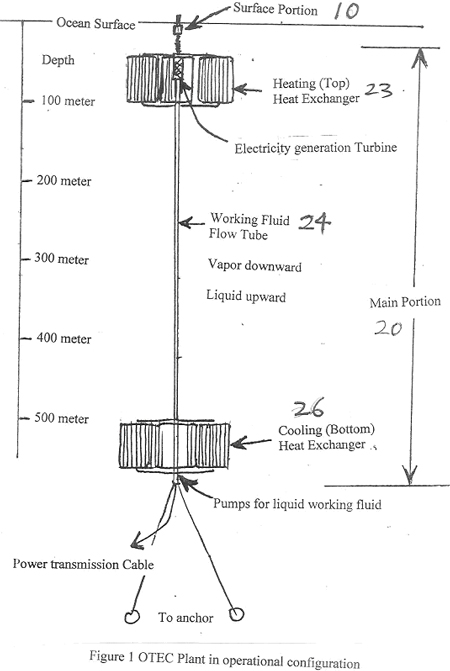

The proposed OTEC plant is depicted in a sketch (figure 1 in previous page). Only the working fluid (ethane) is under “forced” circulation. There is no need to move either cold or warm seawater. The working fluid shall be transferred from the warm region to the cold region and back to the warm region inside the steel (or steel and reinforced concrete) tube.

Semi-submerged structures anchored to the ocean floor will be used to secure the OTEC plant. The 6,000 to 10,000 ton structures (may include enclosed water) should have enough stability. There is a lot of mass to be included in the design to achieve stability.

At 500 meter depth, the seawater pressure is about 800 psi. The seawater temperature is about 10 C. Carbon steel with 40,000 psi strength containing low pressure gas inside will need minimum wall thickness to radius ratio of 1 to 50. For steel tubing to reach neutral buoyancy the wall thickness to radius ratio should be 1 to 16. Leak tight steel tube with neutral buoyancy is perfectly capable of operation in the depth under consideration.

Biological fouling of the heat exchanger tube from the inside is impossible because only the clean working fluid moved inside the tubes. At 500 meter depth, biological activity is much reduced so that the bio-fouling of the heat exchanger tube exterior is practically non-existing. Even for the warm water heat exchanger near the surface, the naturally circulation seawater will not severely affect the performance. As long as the biological activities do not severely impede seawater to working fluid heat transfer through the steel tube wall (with all coatings to control corrosion), the OTEC plant will function near peak capacity. Periodic cleaning of the top heat exchanger, if necessary, would significantly increase the OTEC plant operating cost.

The heat exchanger to seawater interaction may cause convective seawater flow. If the convective flow is strong, the heat exchanger may effectively be able to interact with more seawater and allow the OTEC plant to operate at higher power capacity. As indicated in the previous section, the stored energy in the ocean surface is more than equivalent of 100 days (2400 hours) of continuous solar radiation, even slow water circulation will be able to help extract the thermal energy farther away from the OTEC plant. The natural circulating effect allowed any OTEC plant expelled wasted heat to be used again.

At 500 meter depth, the water temperature is about 10 degrees Celsius. It is my opinion that the addition 6 degrees Celsius of temperature difference that can be obtained at greater depth is not worth the effort. If all the energy in water at above 4 degrees Celsius is regarded as available, the energy reservoir is about three time the value estimated in the previous section. More careful analysis may be able to find the optimum OTEC plant bottom depth.

The power generating turbine should be placed near the surface so that it is easier to service the turbine. It may not be necessary to insulate the warm water tubing feeding into the turbine. The used working fluid (carbon dioxide) would descend to the ocean depth in non-insulated tubing. As indicate later in this section, the working fluid flow tube should be large enough to allow human in protective suit to inspect the tube interior. For more extensive facility service, it may be necessary to bring the OTEC plant to the surface. The heat exchangers may be placed on floating barges. The main working fluid flow tubes may be separated into 12 to 36 meter long segments. The components may be returned to the shore servicing facility. The initial effort should concentrate on functional plant to verify the projected performance.

For power output of 12 megawatt, the higher pressure gas needs to generate about 15 megawatt power with the primary turbine. Carbon dioxide vapor pressure at 28 C is approximately 970 psi. The nominal designed turbine inlet pressure may be set at 960 psi. The nominal designed outlet pressure is 650 psi, slightly higher than the carbon dioxide vapor pressure of about 641 psi at 9.4 degree Celsius. For the 960 psi to 650 psi carbon dioxide gas to generate 15 megawatt of power, the required flow rate is about 5 cubic meters per second. With this established flow rate, the size of the working fluid flow tube is determined by the working fluid flow speed. Higher flow speed would lead to higher energy loss. Lower flow speed will lead to large diameter and heavier OTEC plant. The initial proposal is to use 2.2 meter diameter flow tube to accommodate both the downward (warmer fluid as vapor) and upward (cooler fluid as liquid) flow. The total cross sectional area is about 4 square meters. The smaller tube (about 0.5 square meter cross sectional area) for carrying the condensed working fluid upward is placed inside the main tube (3.5 square meter cross sectional area) that carry the vapor toward the bottom. The required flow speed is about 1.5 meter per second. It is noticed that working fluid operated at higher pressure would need less volume to generate similar power so that the flow rate may be reduced. My opinion is that ethane as in the proposed design is a satisfactory working fluid. It is worthwhile to investigate if there is better working fluid.

The effective flow channel length for either warm or cold section is about 500 meters. The carbon dioxide density (960 psi at high temperature side and 650 psi at the low temperature side) is about 300 kg/cubic meter. For effective flow tube cross sectional area of 4 square meter, the carbon dioxide vapor volume of 2,000 cubic meter will have mass of about 600,000 Kg (600 metric ton). Carbon dioxide inside the heat exchangers and the liquefied fluid transported upward would cause the total mass of the carbon dioxide to be on the order of 3000 tons. A reservoir to replenish leakage lost or other operational condition change would add to this carbon dioxide requirement. The additional cost of using a higher pressure working fluid (not yet identified) may be prohibitive.

The proposed OTEC plant used 100 mm diameter aluminum tube with 3 mm thick wall as the heat exchanger. Using the thermal conductivity of 70 Watt/(m-K) for 5086 marine grade aluminum, each meter length of the tube will be able to transfer heat at the rate of:

(200) (0.08)(π)(1)(1)/(0.003)

= 17,000 (Watt)

of heat (thermal energy) if the interior working fluid to the outside seawater temperature difference is 0.1 degree Celsius. The actual temperature difference between the heat source and the working fluid should be greater as the working fluid first enter the heat exchanger. If we want the temperature between the heat source and working fluid to be only 0.05 degree, the heat transfer rate would be greatly reduced. For a 12 MW (Megawatt) generator, where 15 MW heat transfer at either warm and cold side is necessary, the required heat transfer will need 10,400 meter total tube length. Using 40 meter length tubes, 260 tubes will be sufficient. However, the total tube cross sectional area is only 1 square meter, much less than the nominal 4 square meter. The proposed design therefore uses 7776 40 meter length tubes. The total cross sectional area for the heat exchanger tubes is more than 35 square meters. This calculation indicated that heat transfer is not a limiting factor for getting more thermal power. The heat exchange tubes in the proposed design have been lengthened so that the working fluid inside would have more time to reach the desired temperature (about 0.1 Celsius lower than the outside waster temperature in the hot zone). When the working fluid is in the liquid state, the required flow tube cross sectional area will be much smaller. The design details will not be included here.

Like electric power plants using water-steam as working fluid, the input heat is required to change the working fluid in the liquid state into the vapor phase in the boiler section. The heat is released at the cooling end when the working fluid in converted into liquid. The latent heat of evaporation would cause the amount of heating and cooling to be higher than the energy generated. This concept uses carbon dioxide near its critical temperature and pressure so that the addition of latent heat will increase the heat exchange size by a factor of less than three.

Because of the high heat exchange capacity, the cost optimum design may be to increase the working fluid flow rate. The proposed design at the doubled flow rate may be able to generate twice the rated power and be even more cost effective. I prefer to delay the design optimization until the construction of the ocean model so that the theoretical calculation can be confirmed by test data.

The most effective working fluid is the material that has the greatest pressure differential between the hot and cold heat exchanger. I am completely at a lost to know why no previous OTEC design tries to select the optimum working fluid.

After the working fluid exit the main turbine, the vapor flow toward the bottom of the OTEC plant and is cooled at the bottom temperature (10 degree Celsius) with the bottom heat exchanger tubes. The condensed liquid at the bottom of the condensation cavity is then transferred to the high pressure portion using a series of pumps and (may be thermally insulated) tubes to the warm environment near the surface. The high pressure tubing shall passed through the high temperature heat exchanger and eventually reach the main turbine inlet.

The anchor portion should provide the system with more than 2000 tons of force to prevent movement. The submerged portion should have almost neutral buoyancy. The surface portion can have 500 to 1,000 tons of positive buoyancy. Concrete with moderate strength, resistant to corrosion and high mass is likely to be the preferred construction material. The cost of steel reinforced concrete is about 300 dollars a ton (600 dollars a cubic yard). To keep the support structure cost down, the quantity of concrete use should be minimized. Letting water into part of the support structure would increase the inertia of the structure and enhance stability. The structure would be build near the shore and move to the place of deployment. The 500 meter long flow tube with 2.4 meter outside diameter (inside cross sectional area of about 4 square meter) should be about 2,500 tons in weight. Making space for turbine and hydrolysis equipments will increase the submerged portion to about 4,000 tons. Including the floating portion, the OTEC plant total mass is about 8,000 tons. The cost is about 10 million dollars.

The surface portion is most likely to be stressed during severe weather. If cylindrical shape structure rise to a height of 15 meter above sea level is able to withstand the most severe weather, this design will be used. The cross section of the near surface or above surface region may use the airfoil stream line shape. The top region of the surface portion will align with the primary wind and water flow direction to minimize stress. If the desire is to minimize the stress during severe weather, the complete OTEC Plant may be submerged. The complete structure need to be at neutral buoyancy. Pressure sensor should be able to determine the depth of the surface portion. Pumps to control the amount of sea water in the ballast tank should be able to control the buoyancy. If the originally surface portion is brought down to 100 meter depth, the bottom region of the main portion may be at 600 meter depth. The pressure is still less than 1000 psi, well within the strength limit of the structure.

Using 12 MW generator operating for 8350 hours in a year at rated power as base line, each OTEC plant will be able to generate 1.0 x 10 8 KWH of electricity every year. The wholesale price for electricity is estimated to be 2 cents for each KWH. Yearly product value would then be 2,000,000 dollars. Less than 10 years is necessary to recover the investment. The world wide electricity need can be satisfied with about two million OTEC plants. As long as the cost of energy is competitive, the market place will support continuing addition of OTEC plants.

The active elements of the OTEC plant (turbine, electric inductor, pump, valve, sensors, Flow tube and heat exchanger) are likely to have positive buoyancy. To achieve the near neutral buoyancy condition, ballast materials will be included. The flow tube and the heat exchanger which account for 80 % of the active element mass can be made using steel (about 2000 USD per ton) and aluminum (4000 USD per ton). The total cost for steel and aluminum (1250 ton each) would be at a cost of about 2.5 and 5 million USD. The 3000 ton ballast material can be obtained at about 600 USD per ton so that the cost for ballast is about 2 million USD.

In summary, the proposed OTEC plant includes three important changes that were not in the 1980 experiment. They are:

1. Eliminate ocean bottom cold water transport tube to reduce size (volume).

2. Use off shore neutral buoyancy main portion to avoid weather damage.

3. Use carbon dioxide (or other fluid with greater cold and hot pressure differential) to increase generated power.

Energy contained in each barrel of gasoline is about 5100 mega-joules. Each kilowatt hour of electricity is equivalent to 3.6 mega-joules of energy. Each barrel of gasoline (or product from petroleum) at perfect efficiency would be able to generate about 1,400 KWH (kilo-watt-hour) of electricity. If we want to use 2.5 cents per KWH hour as the threshold for efficient electricity production, (rejecting all methods with higher cost), then gasoline (or petroleum product) at 40 % electricity conversion efficiency must be available at 14 dollars a barrel. The 2008 March gasoline price is about seven times higher. Oil fired generator would therefore be able to provide electricity at 18 cents per KWH.

Assuming that the liquefied hydrogen collected at OTEC plants will eventually be used to generate electricity at 40 % efficiency, the 12 megawatt OTEC plant would become a power source of only 3.2 megawatt. The yearly product value for the converted electricity would be reduced by 74 %. The yearly energy output would be 2.6 x 107 kwh. At the more realistic 6 cents per KWH, the yearly product value would be 1.560,000 dollars. At the 10 cents per KWH rate, the value of the yearly produced electricity would be 2,600,000 dollars.

For myself as a resident in Southern California, My electricity cost is about 14 cents per KWH. I am sure the electricity providers include their profit in the price. A more complete analysis of the cost structure of existing and projected energy source is necessary to generate more precise comparison.

The floating (but anchored) OTEC plant may be built in floating assembly facility in moderately deep water (600 meter depth minimum) and moved to the final operating location. The bottom portion of the OTEC plant (with negative buoyancy) shall be assembled first above the ocean surface. The assembled portion is then lowered into the ocean so that the assembly facility is able to construct the upper portion. Motor of about 2000 horsepower should be able to move the semi-submerged structure at moderate speed (less than 5 Knots) to its final operating location from the assembly location.

The assembled OTEC plant in construction and operation area should be able to continuously generate electricity. After the OTEC plant construction The OTEC plant should be towed toward the operation site through the ocean. The 12 Megawatt power (16,000 hp) is two third the published power of the Trident submarine (24,000 hp). Given that the Trident submarine have the streamline shape, OTEC plant transportation will be much slower. The OTEC plant transportation can be achieved without using outside energy.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.

Featured Product

Vecoplan - Planning and implementation of complete processing plants in refuse derived fuel production

In order to reduce the costs involved in the energy-intensive production of cement, many manufacturers are turning to refuse-derived fuels (RDF), considerably reducing the proportion of expensive primary fuels they would normally use. Solid fuels are being increasingly used - these might be used tyres, waste wood or mixtures of plastics, paper, composite materials and textiles. Vecoplan provides operators of cement plants with proven and robust components for conveying the material and separating iron and impurities, efficient receiving stations, storage systems and, of course, efficient shredders for an output in various qualities.