Solar is one of the most talked-about alternative energy sources in the world today. Enough energy comes from the sun in one hour to power the global population for a year. Even though the amount of sunlight varies around the world, sunlight is a totally renewable resource, unlike oil, coal and natural gas. As long as life exists on the earth, sunlight will play a role.

The Science of Solar: Solar Energy - The Basics

Contributed by | Dow Corning Solar

We know that our sun is actually a very large and hot star emitting lots of power in its rays. How do we go about harnessing that power effectively, so it can help generate electricity, which is an important part of modern life? The sun’s rays transmit both heat and light. The heat is used in thermal systems to produce hot water and hot air for commercial and residential heating use, as well as power generation with steam or sterling engines. The light is used in photovoltaic systems to convert light to electricity, and this is one of the main areas where our solar industry is concentrating its efforts today.

The solar industry, like many others, has its own unique vocabulary.

PHOTO (LIGHT) + VOLTAIC (PRODUCES VOLTAGE) = PHOTOVOLTAIC (PV) SYSTEM

Solar modules consist of layers of materials like a sandwich. A solar cell is made from a thin wafer of silicon, similar to computer chips, but bigger. The light carries energy into the cell, and the cell and the wires connected to the cell convert the light energy into another kind of energy — electric current. No electricity is stored in the cell. If you want to understand more about photons and electrons and how this all works, a quick video tutorial is available: www1.eere.energy.gov/solar/video/solarcell1.mpg.

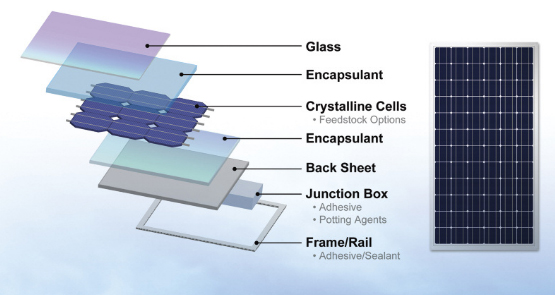

Figure 1 Solar cells are connected to form a module, then mounted in a frame to create a solar panel.

Solar cells are interconnected in a matrix to form a module. One solar cell produces electricity at a voltage of approximately 0.5 volts at room temperature, so 36 cells connected together in a module produce roughly 18 volts. However, the solar cell heats up while exposed to the sun, reducing the operating voltage to about 14-15 volts. A 12-volt battery needs about 14 volts to charge it, so the 36-cell module is the standard used in charging 12-volt batteries.

The cells are connected and placed between a tough glass front and a back surface within a frame and sealed, as shown in Figure 1. Dow Corning is developing encapsulant technology to protect the cells in the module. The encapsulant keeps out moisture and contaminants which could cause the module to fail, so it is a critical part of the manufacturing process. Dow Corning ® brand products are also used to seal the frame, adhere the junction box on the back of the panel and fill the junction box. The potting agents that fill the junction box protect the electrical components it contains.

Once assembled, the panel is ready for installation. Additional equipment is needed for off-grid systems, including a battery storage system. Off-grid systems are standalone units that do not feed electricity back to a power company.

An example of an on-grid system is the solar panels installed by Dow Corning and Hemlock Semiconductor Group at the Dow Diamond baseball park, where the excess power generated is sold back to Consumers Energy, the local utility company. The panels generate electricity year-round.

We learned about how sunlight is converted into electricity using solar cells, which make up modules and arrays. Harnessing the power of photons and electrons to produce electricity is an amazing thing. Using the sun to do it provides a sustainable and reliable source of energy for both residential and commercial buildings. If the sun were to fail, the earth would cease to exist as we know it.

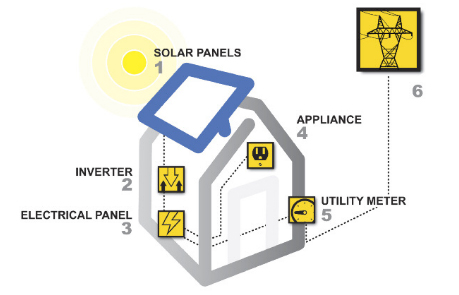

BUT HOW DOES SOLAR POWER WORK IN A RESIDENTIAL HOME?

- The solar panels on the roof convert the sun’s energy into direct current (DC) electricity.

- The current flows to an inverter, which converts the DC into alternating current (AC).

- Where it is diverted to power...

- ...an appliance, for example a lamp, or sent to...

- ...the utility meter, which feeds it to...

- ...the general electricity grid to which the home is attached.

During time when excess electricity flows to the grid, the utility meter will run backward, giving the homeowner credit for contributing electricity to the grid. Note that electricity produced from solar is not stored anywhere along the line.

This is a simplified explanation of the process, and it sounds like a great idea. Could you save money by installing solar panels and generating solar power where you live? Could you avoid putting tons of CO2 into the environment by using a “clean” energy source like the sun? Visit: www.findsolar.com/index.php

Employees at Dow Corning’s Wiesbaden site in Germany have the opportunity to see solar panels in action every day. More than 1,000 square meters of solar panels were installed on the roof and façades of office and production buildings. The energy generated by the solar panels is fed back into the local electricity grid. In return, the company benefits from subsidies to buy electricity for its own energy needs. Dow Corning Wiesbaden commits to reinvest 30 percent of these subsidies every year in sustainable energy projects aiming to reduce the site’s total energy consumption. The solar panel modules were supplied by Photowatt International SAS, one of the largest manufacturers of solar silicon ingots, wafers, cells and modules in Europe. They contain Dow Corning® brand materials developed for use in photovoltaic cells and modules.

Dow Corning and Hemlock Semiconductor Group both play significant roles in the solar energy industry. Dow Corning provides materials and services for the entire solar industry, from the basic building blocks of silicon feedstock for ingots and wafers production to solar module frame assembly and sealing materials. Hemlock Semiconductor is a world leader in the production of polycrystalline silicon, the cornerstone material used to produce solar cells that harvest energy from sunlight.

Dow Corning Corporation, based in Midland, Michigan, provides performance-enhancing solutions to serve the diverse needs of more than 25,000 customers worldwide. A global leader in silicon-based technology and innovation, offering more than 7,000 products and services, Dow Corning is equally owned by The Dow Chemical Company and Corning, Incorporated. More than half of Dow Corning’s annual sales are outside the United States.

Hemlock Semiconductor Group is a world leader in the production of polycrystalline silicon and other silicon-based products used in the manufacturing of semiconductor devices and passive solar cells and modules. Headquartered in Hemlock, Michigan, Hemlock Semiconductor is owned in majority by Dow Corning Corporation. For more information, please visit hscpoly.com.

LEARN MORE Dow Corning has sales offices and manufacturing sites, as well as science and technology laboratories, around the globe. For more information, please visit dowcorning.com/solar or e-mail solar.solutions@dowcorning.com.

The content & opinions in this article are the author’s and do not necessarily represent the views of AltEnergyMag

Comments (0)

This post does not have any comments. Be the first to leave a comment below.